Industrial workplaces are dangerous! As we outlined in our Automotive Assembly blog, the vehicle manufacturing industry reports a significantly high number of injuries. From working with the thin gauged metal required for the systems in today’s electric vehicles to the metal used in all automotive frames, not wearing gloves isn’t an option for workers interested in keeping their hands safe and protected.

When gloves are not worn, there’s no mistaking a worker’s cuts, scrapes, bruises, or permanently grease-stained hands and black fingernails. Whether on the factory floor or in a small-town garage, working on automobiles means cramming hands into tight spaces filled with sharp metal corners, oils, and abrasive objects.

A worker’s hands when gloves are not worn.

Humans have worn gloves for thousands of years to protect their hands. These were often leather gloves with limited dexterity and little to no cut protection. Then, glove innovation blossomed in the 1970s. OSHA was formed and glove makers determined that some of the polymers developed during World War II could offer customers easier to wear gloves with increased protection. For the first time, cotton gloves began being dipped in and coated with rubber latex.

Since the 1970s, gloves have continued to get thinner but stronger, using superior fibers like DuPont™ Kevlar®, Dyneema®, and MCR Safety’s Hypermax®. Both advanced coatings and fibers have helped MCR Safety manufacture extremely lightweight gloves. Since automotive workers, especially assembly specialists, are feeling bolts, components, wires, and parts, they must rely on gloves that provide an abrasive coating and are super thin for increased dexterity.

Today, we want to highlight the thin featherweight work gloves styles available to workers. We’ve come a long way in glove technology and development over the past five decades!

Leather to Seamless Knit Gloves

Leather gloves still fulfill a need in the marketplace, as they have for thousands of years. They are durable and offer high levels of abrasion protection and heat-resistance for activities such as welding.” Unfortunately, leather gloves are traditionally stiff and bulky, rendering them wholly unsuited to use when assembling nuts and bolts onto vehicles.

A leather glove designed by Shakespeare’s father for the purpose of

using a bow and arrow.

So, is there one glove you can use across your entire facility? Next time you ponder that question, just remember the bow and arrow glove pictured above. Application-specific gloves have been around for hundreds of years. Don’t risk a worker’s safety by applying a “one-type meets all needs” approach if the only purpose is to consolidate gloves for financial concerns. A one glove solution doesn’t exist for all workers, especially in an automotive plant.

Some workers may still need leather gloves for welding automotive parts or frames, whereas other workers may need an ultimate sense of touch glove to feel small parts. All gloves have their purpose and place in an automotive facility.

Finding the Best Balance

Unlike leather gloves, string knit gloves conform to the hand better and offer more dexterity, but often at the expense of strength and protection. The key is finding the optimal balance between the features users demand and what makes practical sense.

It turns out that finding this balance is actually pretty simple. As mentioned above, today’s glove production combines the use of modern fibers with updated manufacturing techniques that engineer a stronger, more durable, thinner thread, and knit it into a high-gauge glove that combines comfort, dexterity, and protection into one affordable package.

Using technology to enhance glove performance is just what we’ve done at MCR Safety!

Gauge Breakdown

![]()

![]()

![]()

![]()

![]()

Ok, so we just used a foreign word many will not recognize: gauge. What is it? When glove manufacturers, like MCR Safety, throw out a term such as gauge, they are referring to the number of knitted stitches per inch in a glove. The bigger the gauge number, the tighter the knit, with more stitches per inch than gloves with a smaller gauge number. The gauge simply refers to the number of stitches per inch in a glove.

Here is a breakdown of each gauge:

- 7-gauge

Seven stitches knitted per inch, heavy-weight styles

- 10-gauge

Ten stitches knitted per inch, medium-weight styles

- 13-gauge

Thirteen stitches knitted per inch, lightweight styles

- 15-gauge

Fifteen stitches knitted per inch, ultra-lightweight styles

- 18-gauge

Eighteen stitches knitted per inch, featherweight styles

The lower the gauge number, the fewer the stitches, but the thicker the thread. Thick thread usually offers better protection but less dexterity. Thinner thread allows better movement and sense of touch, but usually doesn’t offer as much protection or last as long. From a user standpoint, this language is useful because higher-gauge products are traditionally more comfortable and provide greater dexterity. Advanced fibers have allowed us to "push the needle" and introduce cut resistant gloves in a higher gauge.

Here are two examples from the gloves we manufacture that utilize DuPont™ Kevlar®. You can see how the 13-gauge 9397 has tighter stitching than the 7-gauge 9370.

13-Gauge 7-Gauge

For automotive workers, a higher gauge glove equals better productivity and increased hand dexterity for grabbing parts, tools, and wires. This means an increase in the bottom line because of increased performance. Plus, higher-gauge gloves are cooler, offer additional comfort, and are form fitting. MCR Safety’s online glove catalog allows you to quickly navigate across different gauge options to select the right one for your needs.

From here on, we will focus only on 18-gauge glove options.

Feeling the Way

MCR Safety offers a full line of 18-gauge gloves designed to meet a variety of needs. From a worker's standpoint, this means being able to control tools, feel engine parts, and attach bolts. Here is MCR Safety’s line-up of 18-gauge, cut, general purpose, and chemical-resistant glove styles. Here are some work places where thin gloves are needed:

- Assembly

- Detail Work

- Driving and Working

- Package Handling

- Small Parts Handling

- Warehouse work

- Wire Handling

- Working outside

High Sensitivity Cut Resistant Gloves

Cut-resistant super thin gloves for people that work with hands seemed impossible at one point in time. However, with advanced high-performance fibers, nothing is impossible. Now, the question is how thin a glove can go and remain cut-resistant. Let's breakdown some glove options.

PU Coated Gloves

Great for feeling small parts, nuts, bolts, and common materials used in assembling vehicles.

PU coating – 92728PU, 92718PU, 9672DT2, 9828PU

Nitrile Coated Gloves

Great for use around oily parts and abrasive hazards.

Nitrile coating –

9818NF,

96782,

90780,

9388NF,

92718NF

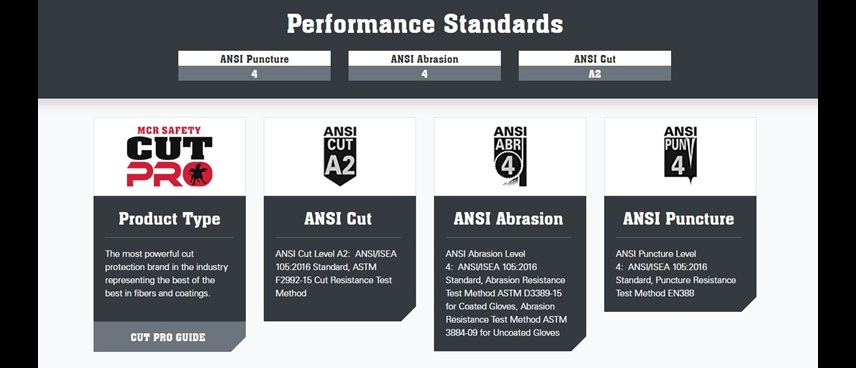

92718PU - thin durable work Glove with cut-resistance

As we mentioned, we’re using state-of-the-art advanced fibers.

92718’s Hypermax® shell provides users with ANSI 4 abrasion resistance,

ANSI 4 puncture protection and A2 cut protection.

92718PU Performance

Best Thin Cut-Resistant Work Gloves

Here are some other featherweight, thin cut-resistant gloves you should

consider. We've highlighted the features and benefits of each one!

9828PU - thin but strong cut-resistant glove

Thin but Strong General Purpose Gloves

PU Coated Gloves

Great for feeling small parts, nuts, bolts, and common materials used in assembling vehicles.

PU coating – N9696

N9696 - provides excellent sense-of-touch

The N9696 is a lightweight option that provides comfortable abrasion protection and a “second skin” barehand feeling for enhanced tactile sensitivity. Compared to 13G PU general purpose styles, MCR Safety’s Ninja Lite glove is 30% lighter. Anyone touching and assembling objects that don’t involve cut hazards should be wearing this glove!

Nitrile Coated Gloves

Great for use around oily parts and abrasive hazards.

Nitrile coating – N96970

N96970 - Breathable thin flexible gloves

18G Chemical - Waterproof Work Gloves

For those who want to stay dry, and steel feel what they're touching, we've got the solution you need.

- PVC/Nitrile Bi-Polymer glove with a 12-inch gauntlet cuff – MG9648

MG9648 offers full protection against chemicals.

Here is a quick link to all of MCR Safety’s 18G products. Our cut-resistant catalog is your next step for all cut-resistant options, including the sleeves that almost all assembly workers should wear.

Our entire 18-Gauge thin work glove catalog

Our entire cut-resistant glove catalog

Forming Better Habits

The simple truth is, workers won’t wear gloves that make their jobs harder. This is especially true if they can’t feel what they’re touching. When that happens, the gloves are coming off. The only way to foster better PPE habits is to provide better PPE equipment.

That might mean spending a little more money on PPE, but our improvements in manufacturing mean costs for cooler, more comfortable products are not as prohibitive as in years past.

Providing Comfortable Protection Options

Injuries are expensive. Quality PPE doesn’t have to be. Our business is helping you stay safe so you can be more productive while remaining comfortable. Using new stronger, thinner fibers developed in recent years, we’ve got you covered!

We welcome any comments, feedback, or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it’s on the shop floor, an oil rig, or a construction site, we are there providing solutions to workplace hazards. It’s all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, request a catalog, find a distributor, or give us a call at 800-955-6887.

Metal Fabrication Application Matrix

Find the appropriate PPE for specific hazards with a simple easy to follow guide.

Eyewear Buying Guide

Each year, more than 2.5 million eye injuries occur. Protect yourself by finding the right eye protection for the job.

About the Author

Related Articles

Advanced Automotive Work Gloves: Modern PPE today’s Assembly Worker Wears

Automotive plant workers are exposed to a laundry list of workplace hazards that require safety...

Personal Protective Equipment: A Look at the Top O*NET Online Occupations Requiring PPE

Are you familiar with O*NET? For any safety manager, the answer should be yes. For those of you...

A Meaningful Review of Metal Stamping and Safety

Metal stamping is the process by which metal is cut and formed into a desired shape or profile by...Latest Articles

.png?mh=200&mw=200&hash=56F65939D291CF35B3AB0C7B6F01AB22)

.png?mh=200&mw=200&hash=9E02057DEDA53C20FCA4D9EDF32AB560)