"The finest steel has to go through the hottest fire"

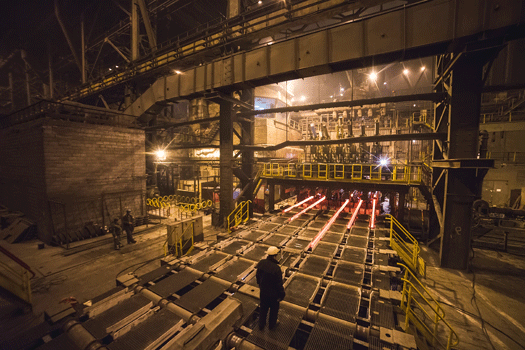

The former US president was spot on with this statement. Blast furnaces in steelmaking reach temperatures of 1600°F to 2300°F. For steel to exist, it truly most go through the hottest fire.

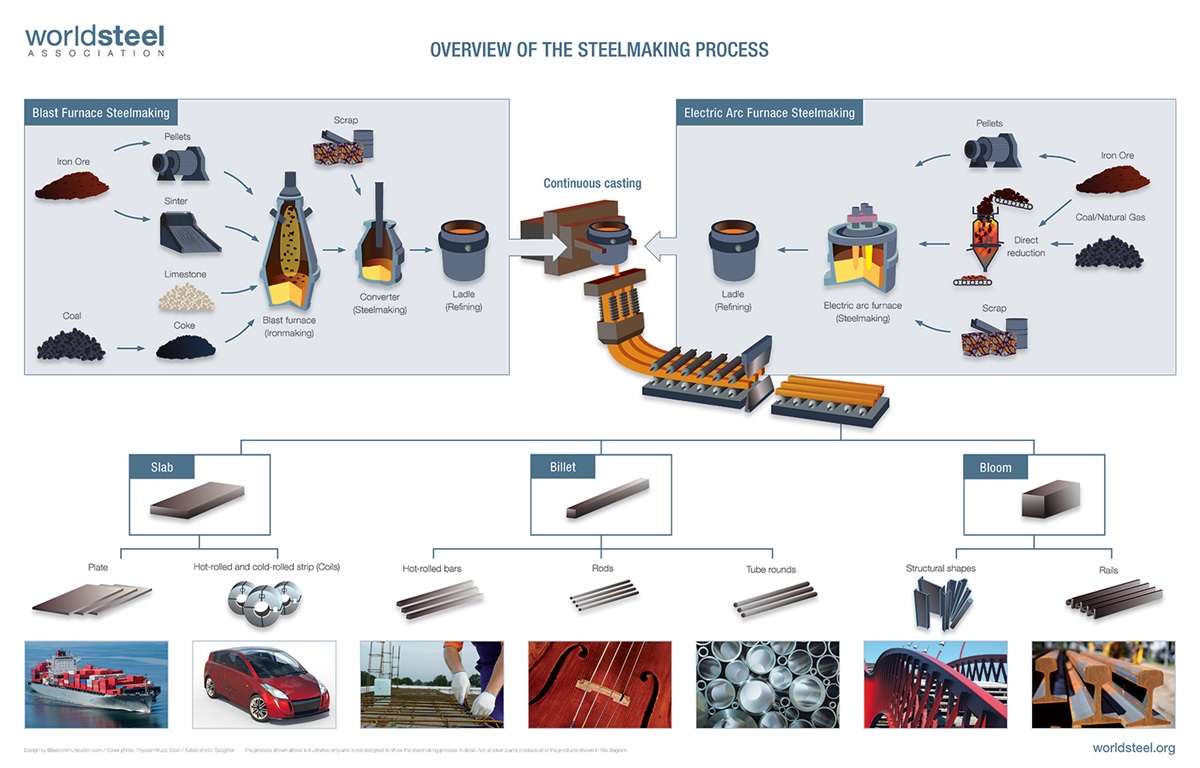

Steelmaking is the process of producing steel from iron ore. Iron and Steel Mill operations consist of Iron preparation, cokemaking, blast furnace work, and finishing operations. The World Steel Association’s Overview of the Steelmaking process will help better visualize this industry.

Throughout the above process, impurities are removed from raw iron, such as nitrogen, silicon, phosphorus, sulfur and excess carbon.

This industry involves companies engaged in one or more of the following:

The industry is broken up based around the production type:

Use a three-step process:

All of these are shown in the World Steel image shown above.

Produce steel from metal scrap. This type of production uses Electric Arc Furnace (EAF) technology, without operations for coking or ironmaking.

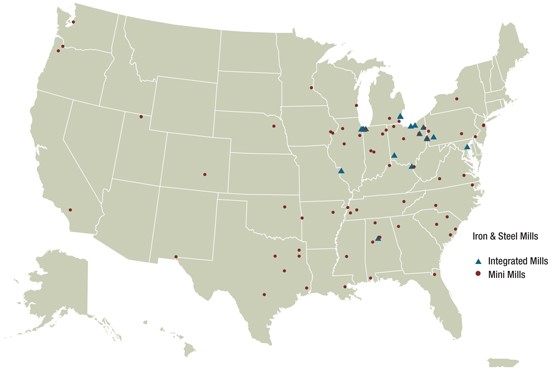

The EPA map highlights where many US Iron and Steel mills are positioned.

Click an occupation to expand and learn more

Perform tasks involving physical labor at construction sites. There are roughly around 2,550 of these workers found in Iron and Steel Mills. You will find these workers using hand tools, repairing drilling equipment, and transporting materials. Common job titles are Helper, Laborer, Post Framer, and Construction Worker.

Operate machines that saw, cut, shear, slit, punch, crimp, notch, bend, or straighten metal. There are around 2,510 of this occupation found in Iron and Steel Mills. You will find these workers aligning metal parts and grinding out burrs or sharp edges. This makes cut resistant gloves a high priority for this worker. Common Job titles for this position are Die Setter, Press Operator, Machine Setter and Operator, Press Punch Operator.

Install, maintain, and repair electrical wiring, equipment, and fixtures. Around 1,860 of this occupation is found in Iron and Steel Mills. You will find these workers connecting wires to breakers and transformers, making dielectric and FR safety gear important. Common Job titles for this position are Industrial Electrician, Journeyman Electrician and Wireman, and Maintenance Electrician.

Operate machines that extrude metal materials into tubes, wires, and bars. Around 970 work in Iron and Steel Mills. You will find these workers loading materials into machines. Common Job titles for this position are Extruder Operator, Wire Mill Remover, Extrusion Press Operator and Metal Inspector.

Operate machines to taper, shape and form metal. There are around 7,470 of these workers found in Iron and Still Mills. You will find these workers removing dies, forging hammers and moving metal work pieces. Common Job titles for this position are Forger, Blacksmith, Hammer Operator, and Forge Presso Operators

Operate grinding tools that remove excess metal material or burrs. There are around 1,130 of these workers in Iron and Steel Mills. You will find these workers sharpening edges and corners, along with polishing metal. Common Job titles for this position are Deburrer, Finisher, Grinder, and Grinding Operator.

Operate heat treating equipment, such as induction and flame-hardening machines. There are around 1,350 of these workers in Iron and Steel Mills. You will find these workers opening furnace doors to load stock and handling many materials. Common Job titles for this position are Burner, Batch Heater Operator, and Heat Treater.

Duties include supplying or holding materials, along with cleaning work areas and equipment. Around 1,520 of these workers are found in Iron and Steel Mills. You will find these workers attaching cables, changing machine gears and handling a lot of material. All of these activities make gloves extremely important. Common Job titles for this position are Laborer, Press Helper, and Material Handler.

Worker activities include repairing, installing, and adjusting industrial machinery. There are around 4,430 of these workers in Iron and Steel Mills. You will find these workers cutting and welding metal to repair broken metal parts. Job titles for this position are Fixer, Industrial and Master Mechanic.

Operate cutting and forming machines. There are around 7,320 of these workers found in Iron and Steel Mills. You will find these workers changing cutting tools, aligning parts, and inspecting metalwork pieces. Common Job titles for this position are CNC Machine setter, CNC machinist, and CNC Operator. Exposure to hazardous equipment is always a concern.

Machinists are the workers who utilize the machine and cutting tools. This occupation is highly skilled at operating machinery. There are around 1,540 of this occupation working in Iron and Steel Mills. You will find this worker operating machine tools to produce precision parts. Job titles for this position Gear Machinist, Machine Operator and Maintenance Machinist.

Help move steel and other materials. There are around 8,670 of these workers found across Iron and Steel Mills. That is a large number of hands needing protected. You will find these workers operating conveyors, transporting materials, and operating machines. Common job titles are Laborer and Operator.

Operate machines designed to cut, shape and form metal. There are roughly 28,130 of this ocupation found in Iron and Steel Mills. You will find these workers fabricating metal products, lifting heavy materials and working with their hands. Be sure to check out our Metal Fabrication industry educational page.

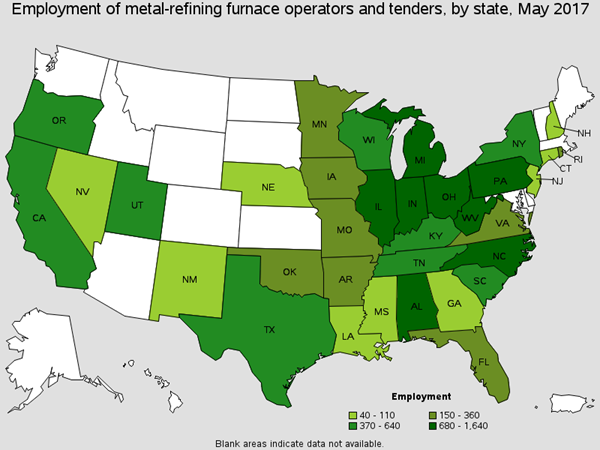

Operates furnaces that melt and refine metal before casting or for constructing various types of steel. Furnace types include gas, oil, coal, electric arc or electric induction, open-hearth, or oxygen furnaces. There are roughly around 5,150 of these workers in Iron and Steel Mils. You will find these workers draining, transferring, and removing molten metal from furnaces and then placing into molds. Common Job titles for this position are Melt Room Operator, Vessel Operator and Central Melt Specialist.

Employement of Metal-Refining Furnace Operators and Tenders by State

Pour and regulate the flow of molten metal into molds. There are around 1,030 of these workers in Iron and Steel Mills. You will find these workers placing materials in molds, moving materials and manipulating things. Common job titles are General Caster, Foundry Worker, Furnace Operator, and Iron Pourer. Around 56% of this entire US occupation can be found in foundries.

Operate machines that plate, roll and flatten steel. There are around 5,630 of these workers in Iron and Steel Mills. You will find these workers around shears, grinders and adjusting machines. Common Job titles for this position are Rolling Mill Operator, Mill Operator and Roll Form Operator.

Use hand-welding, flame-cutting, hand soldering, and brazing equipment to weld/join metal components, fill holes, indentations, or seams of fabricated metal products. There are around 1,700 of these workers are employed in Iron and Steel Mills. You will find these workers welding components in flat, vertical or overhead positions. Common Job titles for this position are Maintenance Welder, Mig Welder, and Welder/Fabricator

Operate welding, soldering or brazing machines that weld, braze, or heat treat metal products. There are around 1,600 of these workers found in Iron and Steel Mills. You will find these workers adding material to work pieces, joining metal components, and annealing finished work pieces. Common Job titles for this position are Fabricator, Mig Welder, Spot Welder, Fitter-Welder, and Braze Operators.

"Safety is as simple as ABC, 'Always Be Careful.'"

You can never be too careful when working around hot and sharp metal, which this industry knows all too well. MCR Safety is ready to meet the safety challenges this industry tackles every day. Check out the hazards we have identified below, along with the recommend safety gear needed for each.

Find the right MCR Safety product that protects you against these common hazards.

Repairing hot stoves, handling steel and abrasive metal requires abrasive resistant gloves.

Learn More About Abrasive Handling ProtectionThere are over 4,000 industrial mechanics working around machines and oily parts. Our coated impact gloves are perfect for this type of work.

Learn More About Crush and Impact Protection

Workers require at the minimum, 100% cotton clothing or FR coveralls acting as a barrier between you and the elements. Max Comfort Safety gear is your ticket to protection.

Learn More About Dirt, Grime, and FR Protection Protection

Coal handling, coke handling and sinter plants generate some dust across Iron and Steel Mills. Check out our lined protective eyewear styles.

Learn More About Dust Protection

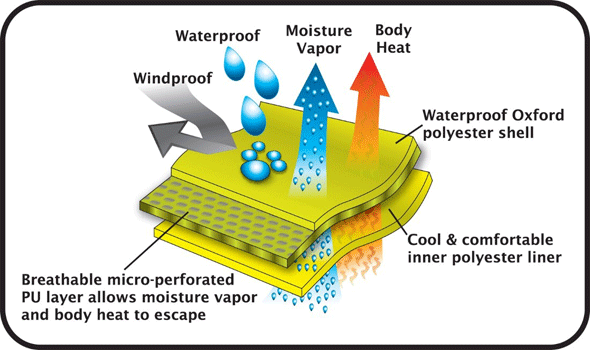

Heat is generated across all steelmaking operations. Breathable raingear utilizes the technology shown in the above image. We also manufacture Breathable Nitrile Foam and Breathable FLT gloves, all designed to keep you cool and comfortable, enough said!

MCR Safety's ITC testing lab tests gloves for ANSI Conductive Heat. Check out our gloves designed for high heat.

Material moving workers need to wear Hi-Vis gear in high traffic areas moving steel.

Learn More About Overall Visibility Protection

Eyewear hazards are in most all areas of an iron and steel mill, from finishing, to grinding, to welding and molten metal. Do not worry; we have styles with 6X greater Anti-Fog technology, perfect for hot environments.

Learn More About Impaired Vision Protection

Spraying steel produces liquid and moisture. Disposable gloves, FR coveralls and goggles are definitely needed when performing this work.

Burrs on steel products can easily cause a laceration. From finishing operations, metal material handling and extruding operations, cut injuries are always a concern.

Learn More About Sharp Objects Protection

The saying goes, "You don't know what you don't know". Let our 360 team help you know more abut PPE.

Learn More About Lack of Safety Knowledge Protection Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.