The Importance and Significance of ANSI Standards

Posted by Anthony Webb on Oct 28th 2024

ANSI Standards

ANSI standards have crucial value to the safety programs used in a variety of industries nationwide. Although consumers are not always familiar with ANSI standards, they protect the environment and people's health and safety. Plus, they ensure that different products are compatible under one set of instructions, making people's lives easier, safer, and more enjoyable.

The ANSI standards drive the decision-making and development of all personal protective equipment (PPE), so they deserve some time in the spotlight. This article will take a more in-depth look at the standards and how they serve such a critical role in protecting people at work.

The Organization

What is ANSI? Founded in 1918, the American National Standards Institute (ANSI) is a nonprofit organization that oversees and sets U.S. standards, conformity, and norms for products found in nearly every U.S. sector.

The organization was initially called the American Engineering Standards Committee (AESC) and was primarily focused only on engineering standards. Then, in 1928, the organization was reorganized and named the American Standards Association. Over time, it developed partnerships with numerous global organizations, such as the International Organization for Standardization (ISO), and was eventually renamed in 1969 to its current ANSI title.

Today, ANSI standards are present in virtually every industry and regulate standards and qualitiy control in over 270,000 different companies, promoting U.S. safety standards worldwide.

The Standards

What are ANSI standards? As ANSI explains in their literature, a standard is an agreed-upon way of doing something. For PPE, this agreed-upon way ensures that the PPE workers wear equipment designed to keep them safe, with an adopted minimum standard and performance level. Those who work on the front line do not want to simply take a company's word that a protective device works. Instead, they want to know it meets specific performance requirements. ANSI standards provide:

- A common language for all involved in bringing a product to market.

- Compatibility of components, making them interchangeable.

- Established and specific levels of performance based on universal testing methods.

- A method for verifying the suitability of a product in different environments.

- Clearly identified requirements for government regulation.

One example of a current standard implemented for gloves is the new ANSI ISEA 138 impact standard. Before its adoption, companies and workers had thrown at them a new wave of gloves that incorporated impact-reducing material on the back-of-hand created by multiple companies. However, there was little guidance as to what different materials did and what protection they offered, which, over time, led to increased confusion as numerous companies began developing impact gloves providing varying degrees of protection.

Thanks to the new standard's ANSI publication, wearers can now choose gloves rated on an impact-protection scale from 1-3. Workers can do their jobs more confidently and focus on their tasks as they worry less about their hands' safety. Similar standards have been established around other glove performance areas, such as puncture, abrasion, and cut-resistance. We will cover each of these performance areas more in-depth below, but first more on the overall process itself.

American National Standards Process

ANSI does not create or even enforce standards (for example, OSHA enforces ANSI standards). They are simply the organization that develops and oversees ongoing collaborative partnerships between industries and the government to address specific standardization needs and identify gaps in existing standards. ANSI coordinates the work of the organizations responsible for developing and writing national standards. There are more than 240 ANSI-accredited standards developing organizations (SDOs), including groups like ASTM International, Underwriters Laboratories, Inc., NFPA International, and the International Safety Equipment Association (ISEA).

ANSI's involvement in the initial process only ensures transparency and due process amongst all the different stakeholders. They work to create an open and transparent medium of communication and information exchange between the various parties involved in bringing a product or service to the market.

The four steps to getting a standard adopted are explained here.

Setting a standard initially begins when an industry works to determine specific, agreed-upon guidelines, requirements, and best practices around products produced for human use. For the impact glove standard mentioned above, a subgroup of the International Safety Equipment Association's (ISEA) hand protection group worked on developing a voluntary standard for over three years, starting in 2016. This work took place in conjunction with seven leading glove manufacturing companies. The guidelines set encompass all aspects of the industry, from the design, operation, manufacturing, and servicing of equipment pieces.

Once a standard is agreed upon, ANSI then supports these voluntary standards to ensure that products from any company also meet the adopted standard and performance level. This requires the cooperation of technical professionals, companies, industry groups, academics, and government and consumer representatives. For the impact glove standard, final adoption took place in 2019. Once approved, an ANSI standard has a five-year duration, then must be reaffirmed every five years.

PPE Standards

Why use ANSI standards for PPE? The American Society of Safety Professionals (ASSP) recommends using ANSI standards for PPE in the workplace, ensuring workers are wearing protection that meets minimum performance and labeling requirements. For safety managers establishing a companywide safety program, products' performance scores pave the wave for deciding what PPE is suitable for the hazards their workers face.

Testing: Gloves, Glasses, and Hi-Vis Garments

MCR Safety takes the guesswork out of determining how products perform by adhering to ANSI standards across our product lines. Below, we highlight each of the different criteria we utilize.

GLOVES

American National Standard for Hand Protection

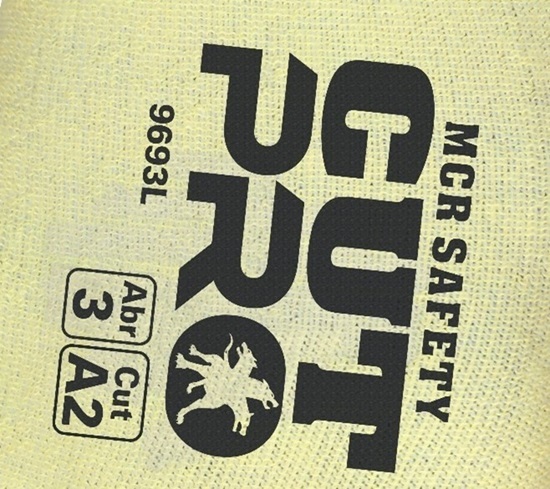

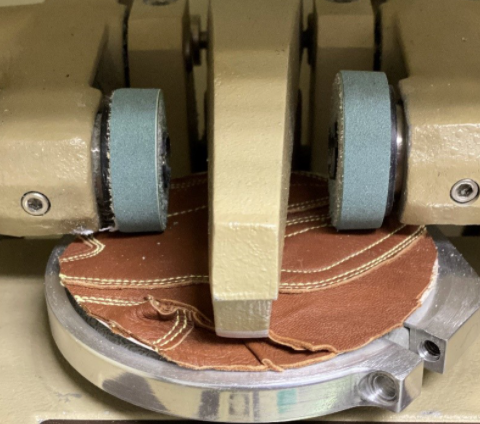

- Abrasion – Gloves are tested following the ANSI/ISEA 105:24 standard by utilizing the ISO 17025:05 accredited test. The purpose of testing for abrasion is to determine how well the glove material resists the loss of mass from rubbing against rough surfaces. A glove that holds up to abrasion is essential for those on a job site who handle abrasive objects like bricks and concrete.

Abrasion Taber Test Machine

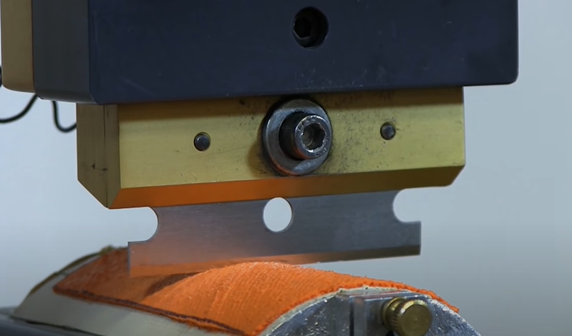

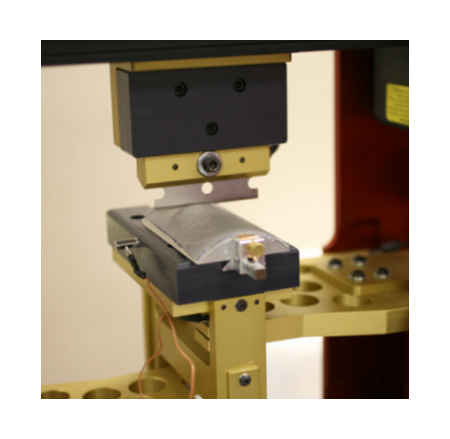

- Cut – ANSI/ISEA 105 uses a nine-level scale of cut resistance, which extends from zero to 6,000 grams and is based on the TDM method of testing that uses a tomodynamometer. The higher the weight required to cut the material, the higher the cut-resistance rating, and the safer workers are from super-sharp objects.

ASTM F2992-15 Cut Test Method

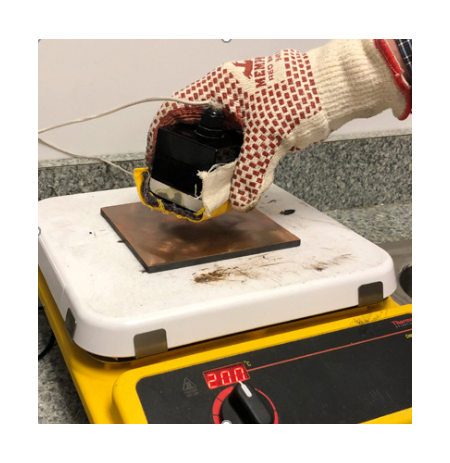

- Heat – Conductive heat testing measures when it takes a person wearing the PPE to feel discomfort and develop second-degree burns when exposed to a given temperature. The ASTM F1060-16 test method is used to determine heat-resistance levels from 0-5.

Conductive heat test using a sensor to determine heat energy transferred to the glove.

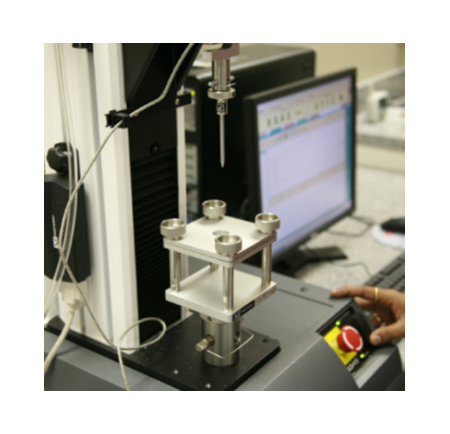

- Puncture – MCR Safety's ITC Lab tests gloves to ANSI/ISEA 105-16 for puncture resistance. It utilizes Clause 6.4 of EN388:2003 as the test method to determine the amount of force exerted by a steel stylus to puncture a glove palm. Performance levels are awarded in accordance with an average number assigned to 12 test results.

Puncture-resistance test using a stylus pushed through the glove's material.

- Tear – ANSI/ISEA 105-2016 provides performance data to assist users in making an appropriate product decision. For tear performance, testing is performed using EN 388-16 test methods, which determines the amount of force required to tear a glove.

Tear-Resistance Testing

Impact Protection

American National Standard for Performance and Classification for Impact-Resistant Gloves

- Impact – ANSI/ISEA 138, in effect since 2019, establishes key requirements around impact gloves.

- Defines an agreed-upon testing method for gloves’ impact protection

- Includes three clearly-defined performance levels

- Specifies a pictogram mark for each of the levels of compliant gloves

- Requires that products be tested in a laboratory with a certificate of accreditation meeting the requirements ISO/IEC 17025:2017, General requirements for the competence of testing and calibration laboratories

More specifically, the standard establishes the “minimum performance, classification and labelling requirements for hand protection products designed to protect the knuckles and fingers from impact forces, while performing occupational task.”

Watch a video highlighting this standard.

HI-VIS GARMENTS

American National Standard for High-Visibility Safety Apparel

- Hi-Vis – To comply with ANSI/ISEA 107-2020, a garment's background material and retroreflective or combined-performance material must be tested by an accredited laboratory. The finished item manufacturer then verifies that the garment or headwear meets all the standard requirements and provides a Declaration of Conformity for each model.

SAFETY GLASSES

American National Standard for Occupational and Educational Eye and Face Protection

ANSI/ISEA Z87.1-2020, the sixth revision of the voluntary eye and face protection standard, establishes performance criteria and testing requirements for devices used to protect the eyes and face from hazards that can potentially cause eye injuries. It also clarifies testing consistency in applying dark-state tolerances for automatically darkening welding filters and determining the minimum coverage area of head forms while it expands welding filter shades.

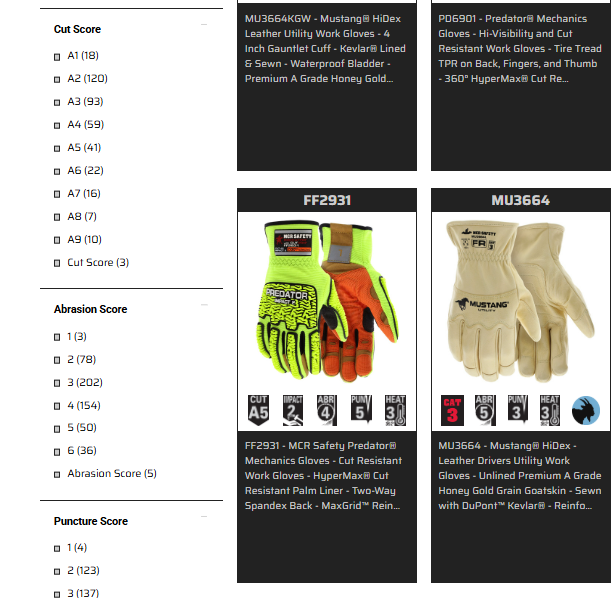

Performance Scores on the Website

Once a user understands the concept of standards and how important they are in developing PPE, they become the driving force of the entire purchasing process. At MCR Safety, we recognize our customers' needs, which is why you will find ANSI filters on our online catalogs' left-hand side, allowing quick navigation to specific products meeting the exact performance level required.

MCR Safety Laboratory

Any company can sell a cut-resistant glove. However, the question you should be asking is, has it passed the quality management testing process of an ISO 17025 laboratory, which validates established performance levels? Neither OSHA nor any government agency audits these tests, so it's up to the purchaser to determine testing accuracy.

At MCR Safety, we don't expect you to put your life on the line based on third-hand promises of protection, so we test our products ourselves, and we offer free testing for our customers. Our Innovations Technology Center (ITC Lab) has been in operation since 2010, testing PPE for cut, abrasion, heat, puncture, impact, and tear resistance. In July of 2016, our commitment to excellence led to the ITC becoming one of the first North American testing labs to receive ISO/IEC 17025:2005 accreditation for Hand Protection. It's an international standard that requires companies to demonstrate a high degree of accuracy and consistency in testing protective equipment.

MCR Safety takes pride in being one of the few accredited testing laboratories in the world. Laboratories accredited to the ISO/IEC 17025:2005 standard have demonstrated they are technically competent, meaning they can produce precise, reliable, and accurate test data.

Entire List

There are over 9,000 ANSI standards that have been developed. We recommend searching ANSI's website for specific criteria you may want to review. You can enter keywords that will take you directly to your area of interest.

ANSI/ISEA safety standards cover a wide range of PPE. All these protective products are essential to ensuring your workers are the safest they can be at their worksite. For those interested in all PPE standards, including those for products outside of what MCR Safety offers, you can view all ISEA standards here. Some you might recognize include:

- ANSI/ISEA 121-2024 – Dropped Object Prevention

- ANSI/ISEA 113-2013 – Portable Decontamination Shower Units

- ANSI/ISEA Z358.1-2014 – Emergency Eyewash Equipment

- ANSI/ISEA Z89.1-2014 – Head Protection

- ANSI/ISEA Z308.1-2015 – Workplace First Aid

- ANSI/ISEA 101-2014 – Disposable Coveralls

- ANSI/ISEA 125-2014 - Conformity Assessment

- ANSI/ISEA 102-1990 (R2015) – Gas Detector Tubes

- ANSI/ISEA 104-1998 (R2015) – Air Sampling Devices

Common Questions

Are ANSI standards referenced in OSHA?

- OSHA can reference specific ANSI standards in their regulations, commonly referred to as "incorporation by reference." OSHA also can require adherence to ANSI standards through the General Duty Clause, which allows OSHA to cite employers for hazardous conditions that are not directly addressed by OSHA but are addressed by ANSI standards.

Can ANSI standards be enforced?

- OSHA often looks to standards bodies like ANSI for an industry's accepted best practices for a safety product or safety approach—and these practices can be cited in litigation. ANSI tends to go above and beyond the minimum requirements of the regulation.

What is the ANSI standard for protective eyewear?

- ANSI/ISEA Z87.1-2020 is the specific standard for safety glasses.

How are ANSI standards cited?

- Iowa State University has a comprehensive how-to guide for locating standards and specifications online, including a Citing Standards section. Since no separate style guide for industry standards exists, ANSI recommends using the Chicago Manual of Style for citations. Citations should consist of some understanding that it is a standard, the issuing agency (or publication name), standard number, standard title (at a minimum), and publication date. Make sure you provide enough information so that anyone interested in investigating further can track down the original document.

Raising the Protection Bar with Standards

Standards establish the minimum performance, classification, and labeling requirements for PPE designed to protect individuals while performing occupational tasks. At MCR Safety, we raise the overall bar and test products to meet specific standards in our very own testing lab.

We welcome any comments, feedback, or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it’s on the shop floor, an oil rig, or a construction site, we are there providing solutions to workplace hazards. It’s all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, or find a distributor, or give us a call at 800-955-6887.