From Leather to Latex: A Comprehensive Look at Glove Materials and Types of Gloves

Posted by Anthony Webb on Dec 5th 2025

What are gloves made out of? Let's first stress this is a complex answer to a relatively simple question most would consider. Protecting today's modern-day workers from all the potential workplace hazards requires a wide assortment of options. So asking us which glove material makes up most of our gloves opens up a lengthy discussion.

Work gloves are essential for protecting workers' hands across almost every industry. They are made from different materials to cater to specific tasks, hazards, and environments. As you can imagine, our glove portfolio has ballooned to over 1,000 gloves utilizing many different materials over time. Today, MCR Safety's work glove lineup consists of roughly 49 materials, utilizing numerous synthetic coatings, man-made fibers, and organic materials. The list of glove materials runs from natural, such as bamboo and cotton, to synthetic string knit materials, such as DuPont™ Kevlar®.

![]()

MCR Safety's work glove lineup consists of roughly 49 different materials used, utilizing numerious different synthetic coatings, man-made fibers, and organic materials.

How did we reach a point where 40+ glove materials were necessary for producing work gloves? Until 1970, leather, cotton, and jersey fabrics represented most of the industry's hand protection offerings. We encourage you to read our OHS article, The Golden Era of Hand Protection, which provides a historical overview of how we got here. We are in the Golden Age of protecting people's hands!

In general, the different materials improve a glove in one of three areas:

- Better comfort

- Better fit

- Better overall protection

So, what are gloves made out of? We will keep this article short as possible and only cover some of the most requested materials for gloves. At the very end of the article, we will also point you toward other articles that dive deeper into glove materials around specific product lines, such as disposable gloves, rain gear, etc. Plus, we provide a rundown of every material and its direct link to our online glove catalog in a roadmap table at the bottom of this article. Let's start highlighting the best materials for gloves!

High-Performance Cut-Resistant Material

Many work gloves incorporate high-performance cut-resistant fibers, essential for workers in industries that involve handling sharp objects. High-Performance materials provide users with the most significant protection. Because of their enhanced features, there has been a progressive shift to utilizing more seamless knit shells as liners.

Since OSHA was founded in 1970, the quality of PPE technology has significantly improved, most notably with the advent of recent cut-resistant technologies. High-performance work gloves offer enhanced abrasion, cut, tear, thermal, and puncture resistance protection. The most common, DuPont™ Kevlar® and DSM Dyneema®, are covered more in the next section.

Let's highlight the most requested high-performance materials in our product lineup.

Aramid Fibers

Aramid fibers create gloves made from a strong, lightweight synthetic fiber that provides exceptional cut and puncture resistance. They are often used in industries that handle sharp objects like glass and metal. Manufacturing industries, such as automotive, are heavy users of aramid-based products.

Below are the two fibers we utilize in producing work gloves:

KEVLAR® fibers withstand temperatures of up to 900° F, making it ideal for cut hazards that involve heat. Its tensile strength is five times stronger than steel in its ability to withstand the amount of tension applied. MCR Safety is a DuPont-licensed manufacturer of KEVLAR® brand fiber. MCR Safety is unique in being the only licensed manufacturer that also spins our KEVLAR® yarn.

MCR Safety released a brand-new aramid cut-resistant fiber in 2020. ARX technology provides both cut and heat resistance at affordable price points!

For more on aramids fibers, check out our article An Overview of Aramid Fibers which highlights this important high-performance fiber.

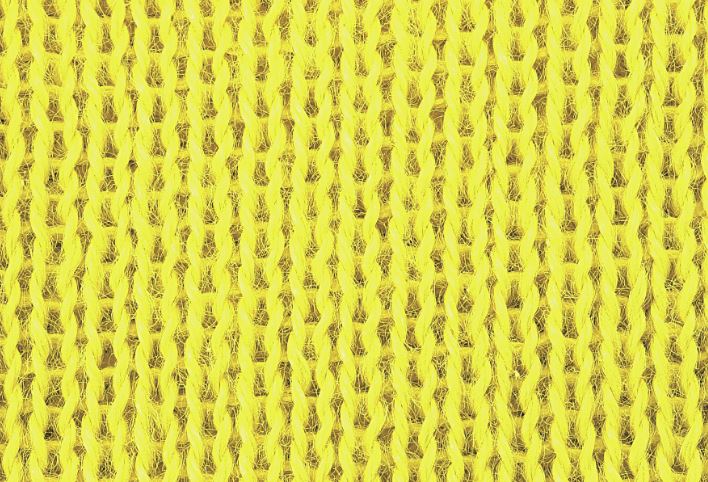

HPPE Fibers

HPPE fibers utilize ultra-high molecular weight polyethylene (UHMWPE) fibers, providing excellent cut and abrasion resistance without sacrificing hand movement. They are used heavily in food processing, metal fabrication, and glass handling industries.

Recognized for being 15X stronger than steel, with excellent abrasion and cut protection levels. Dyneema is recognized as our premium HPPE fiber, achieving superior comfort and protection. Additionally, when combined with fiberglass or steel, it achieves even higher levels of cut resistance.

Similar to ARX, with technological advancements and our years of manufacturing experience, we can provide the market with an excellent, top-performing, cost-effective alternative to current industry-leading HPPE fibers.

Our polyester steel wrapped Steelcore gloves are one of the strongest cut-resistant options MCR Safety offers. They feature strands of stainless steel wrapped with polyester fiber, an ideal material composition for those who need protection while cutting foods. The FDA-accepted material provides low linting, a feature suitable for those in food processing, and it also doesn't shrink after laundering.

Leather Glove Material

![]()

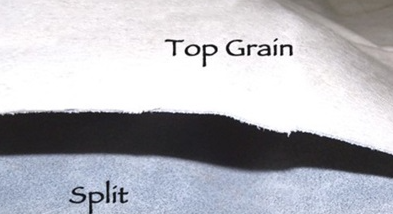

Leather is a traditional and popular material for work gloves. It offers excellent durability, abrasion resistance, and heat resistance. Often overlooked characteristics include absorbing shock and providing good puncture resistance. Below is a good look at the core advantages of leather material.

- Grain leather is the external portion of the hide and provides a smooth, soft, and comfortable leather. Grain leather allows for better hand movement and a sense of touch. It is priced higher than split leather due to its demand from the automobile, furniture, sporting industry, and apparel market.

- The split leather comes from the inner portion of the hide closest to the flesh. Leather’s strength is due to the density of fibers and will vary depending on which portion of the hide is used. Split leather is valued due to its abundance and diversity.

The most common leather glove types are cowhide, goatskin, pigskin, deerskin, and synthetic leather. Each type of leather offers its benefits.

Types of Leather:

- Cowhide: Most commonly used leather within the glove industry due to its plentiful availability.

- Goatskin: Proven to be robust leather with excellent tensile strength. Goatskin also has a natural lanolin content that keeps gloves and hands soft. Goatskin is typically too thin to split and therefore provides greater tactile sensitivity.

- Pigskin: Very abrasion-resistant leather due to its natural fiber makeup. The leather breathes, retaining its softness even after being wet. Pigskin gloves are helpful in wet applications, as these gloves will not get as stiff as cow leather. Pigskins can also be split.

- Deerskin: Known to be one of nature’s most luxurious leathers, providing all-day comfort and great sensitivity to touch due to its softness.

- Elkskin: Recognized as one of the most durable and softest leathers.

- Synthetic: Breathable, lightweight, soft fabric enhances dexterity and gripping properties.

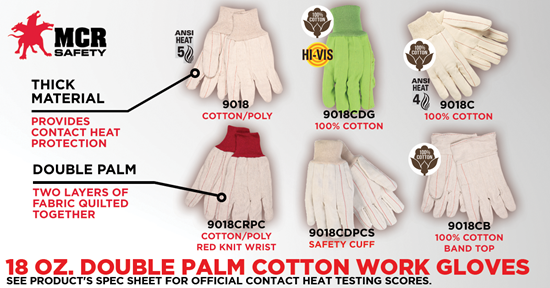

Cotton

Cotton work gloves are known for being lightweight, breathable, and comfortable. The traditional cut-n-sewn cotton glove was one of the first-hand protection offerings ever offered and a staple product recognized for protecting workers' hands. Unfortunately, they offer minimal protection due to limited cut resistance. However, they are a budget-friendly option for general-purpose environments, protect products handled, and provide moderate heat protection. Cotton gloves are a go-to for handling light materials, inspection areas, oil and gas operations, and packaging products.

New introductions include cotton canvas, double palm, and dotted double palm styles available in high visibility yellow, green, or orange fabrics. Below are some common areas in which each cotton style is used.

- Lisle/inspectors: Keeps oil and grease off products, computer chips, low lint applications, cosmetics, electronics, film processing, and pharmacy.

- Chore gloves or Quilted Fleece: Farming, oilfields, and foundries.

- Double palms: Oilfields, foundries, and light heat applications.

- Hot mill: Medium heat applications and some foundry operations.

The cotton canvas material is known for being durable and heavy-duty. Sometimes though, a little extra padding is needed. Our Double Palm cotton gloves include a second layer of material sewn into the palm, providing the wearer with increased protection.

When wearing heat-resistant cotton gloves designed for hot surfaces, your hands are shielded with one of nature's most eco-friendly materials. If you work around heat, consider one of our Hotmill top-selling styles.

Cotton General Purpose Knits

We know there are still customers who only require basic hand protection for general-purpose applications. Cut-resistance and impact protection are fantastic when the situation calls for it. For some, though, like agricultural work or warehousing, a nice pair of durable and soft string-knit gloves are perfect!

Knit gloves were originally designed as glove liners, primarily for general-purpose handling. They have progressed into the most economical general-purpose work glove due to their versatility and comfort. The most commonly used yarns include cotton, polyester, and nylon yarn, either knitted separately or blended.

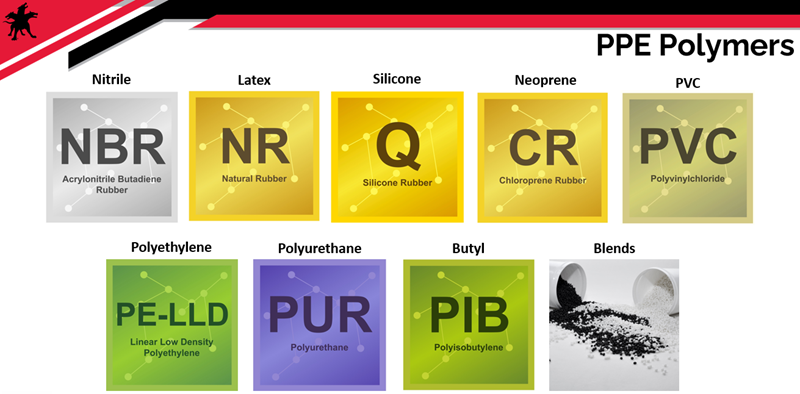

Polymers Used

The remaining materials highlighted some of the top coatings from the above chart we use to develop work gloves.

Rubber Glove Materials

What gloves are made from synthetic rubber? Let's first stress that latex and rubber are closely related but different. Latex is natural rubber; however, rubber applies to a broader class of materials that can be natural or synthetic. Synthetic rubbers can be made from petrochemicals and can be manufactured differently from latex.

Latex is a natural rubber harvested from the sap of rubber trees, particularly the Hevea Brasillensis, via a process known as tapping. It is a milky white sap-like substance trapped beneath the bark of rubber trees. Over 80% of all latex gloves are made in Malaysia, Thailand, Indonesia, and Vietnam. Malaysia alone produces over 60%. Once collected, it becomes preserved in ammonia and used in manufacturing.

The work gloves made from latex offer users excellent flexibility and elasticity, exceptional fit and comfort, and exceptional tear resistance.

Nitrile

What is nitrile? The unique properties of nitrile polymer result from its chemical structure, consisting of acrylonitrile and butadiene. The existence of the nitrile (CN) group in the acrylonitrile units gives the polymer its excellent resistance to oil, fuel, and other chemicals, while the butadiene units contribute to its flexibility and high tensile strength.

Often considered the "jack-of-all-trades" polymer because of its wide usage across industries due to its resistance to oil, water, and chemicals. It is known as the workhorse of industrial industries and is commonly referred to as nitrile-butadiene rubber (NBR) and is the go-to polymer when oil is involved.

Nitrile work gloves are primarily known for being strong, durable, and latex free.

PVC

Polyvinyl chloride (PVC) is a thermoplastic substance known as vinyl. It was first discovered in 1835. However, it took scientists over ninety years to find a use for this material. PVC is produced by polymerizing vinyl chloride and adding plasticizers to unstiffen the material, making it softer. It's the economical solution for industries that only require protection for short periods in general-purpose areas and frequently change out PPE.

Vinyl is not PVC. It's a specific type of plastic made from PVC resin, creating gloves known for affordability and ease of use. Essentially, they are in the same family, but not the same thing.

PVC work gloves are primarily known for being a durable glove, yet also affordable.

Neoprene

Chemically resistant gloves derive from special polymers, such as neoprene or butyl. Neoprene comes from chloroprene rubber, a chemical compound derived from the chlorination of butadiene or isoprene. It contains a high proportion of chlorine atoms, making it resistant to numerous chemicals. Unlike other polymers that excel in a specific area, Neoprene combines many attributes into one polymer: resistance to oil, fuel, continued light exposure, ozone, and oxidization. Neoprene

Neoprene work gloves are primarily known for offering wearers a unique combination of comfort, durability, and excellent chemical, heat, and oil resistance.

Polyurethane

PU is one of the most used polymers for coating knitted shells with a lightweight yet durable coating since it provides excellent resistance to abrasion and good resistance to both ANSI cut and puncture environments.

Polyurethane-coated work gloves are known for being lightweight and flexible, offering the best tactile sensitivity and breathability.

Different Types of Gloves Require Numerous Materials

We've kept it short, as we mentioned above. This means we've only scratched the surface to the 40+ materials. There are butyl gloves, nylon and polyester options, blended options, silicone-coated gloves, metal mesh, winter glove material, terry cloth options, FR Nomex gloves, and numerous others. We've linked the areas in the last sentence to other articles that address those materials. However, we would love to know which materials you need additional information on, so please comment below.

As questions arise or if you have an application that needs further discussion, don't hesitate to give us a call or check in with our distributors. Protective work gloves are critical to workplaces and employee safety, so call us whenever you are in doubt about the protection you require to stay protected.

Click the below image to leave us comments, questions, or any concerns.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether you're handling circuit boards, assembling a PC, or working at a construction site, we provide solutions to workplace hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, find a distributor, or give us a call at 800-955-6887.

Material Roadmap for Work Gloves

We've created the below table to help you quickly navigate to materials identified across our online work glove catalog. As you can see, numerous variations and different materials distinguish specific glove areas.

| Material Location | Material Type |

|---|---|

| Coating | Bio-degradable Nitrile |

| Coating | Butyl |

| Coating | Latex |

| Coating | Neoprene |

| Coating | Nitrile |

| Coating | Polyethylene |

| Coating | Polyurethane |

| Coating | PVC |

| Coating | Silicone |

| Coating | Vinyl |

| Coating | Water Based Polyurethane |

| Glove Back Material | Acrylic |

| Glove Back Material | Canvas |

| Glove Back Material | Cord Canvas |

| Glove Back Material | Cotton Polyester Blend |

| Glove Back Material | Cotton |

| Glove Back Material | Grain Leather |

| Glove Back Material | Jersey |

| Glove Back Material | Nomex |

| Glove Back Material | Nylon |

| Glove Back Material | Polyester |

| Glove Back Material | Spandex |

| Glove Back Material | Split Leather |

| Glove Back Material | Synthetic Leather |

| Glove Back Material | Terry Kevlar Blend |

| Glove Back Material | Terrycloth |

| Impact Material | D3O |

| Impact Material | Foam |

| Impact Material | TPR |

| Impact Material | TPR - D3O Foam |

| Insulated Lining Material | Fleece |

| Insulated Lining Material | Fleece and Foam |

| Insulated Lining Material | Foam |

| Insulated Lining Material | Jersey |

| Insulated Lining Material | Merino Wool |

| Insulated Lining Material | Pile |

| Insulated Lining Material | Thermal |

| Insulated Lining Material | Thermosock |

| Insulated Lining Material | Thinsulate C100 Gram |

| Insulated Lining Material | Thinsulate C200 Gram |

| Insulated Lining Material | Thinsulate C40 Gram |

| Insulated Lining Material | Wool |

| Leather Material Type | Buffalo |

| Leather Material Type | Cow |

| Leather Material Type | Deer |

| Leather Material Type | Elk |

| Leather Material Type | Goat |

| Leather Material Type | Pig |

| Leather Material Type | Sasquatch |

| Leather Material Type | Synthetic |

| Shell Material | Acrylic |

| Shell Material | Aramid - ARX / Steel / Synthetic |

| Shell Material | Aramid - ARX / Steel |

| Shell Material | Aramid - ARX Cotton Blend |

| Shell Material | Aramid - ARX |

| Shell Material | Aramid - Kevlar / Steel / Modacrylic |

| Shell Material | Aramid - Kevlar / Steel / Synthetic |

| Shell Material | Aramid - Kevlar / Steel |

| Shell Material | Aramid - Kevlar / Synthetic |

| Shell Material | Aramid - Kevlar Cotton Blend |

| Shell Material | Aramid - Kevlar Cotton/Polyester Terrycloth |

| Shell Material | Aramid - Kevlar Cotton/Polyester |

| Shell Material | Aramid - Kevlar |

| Shell Material | Cotton Interlock |

| Shell Material | Cotton Jersey |

| Shell Material | Cotton Polyester Blend |

| Shell Material | Cotton Polyester Interlock |

| Shell Material | Cotton Polyester Jersey |

| Shell Material | Cotton Polyester Terrycloth |

| Shell Material | Cotton Terrycloth |

| Shell Material | Cotton Woven |

| Shell Material | Cotton |

| Shell Material | HPPE - Diamond Dyneema / Steel |

| Shell Material | HPPE - Diamond Dyneema / Synthetic |

| Shell Material | HPPE - Diamond Dyneema |

| Shell Material | HPPE - Dyneema |

| Shell Material | HPPE - Hypermax / Steel / Synthetic |

| Shell Material | HPPE - Hypermax / Steel |

| Shell Material | HPPE - Hypermax / Synthetic |

| Shell Material | HPPE - Hypermax 2.0 |

| Shell Material | HPPE - Hypermax |

| Shell Material | HPPE - Spectra |

| Shell Material | Ingenia |

| Shell Material | Nylon |

| Shell Material | Polyester Elastane |

| Shell Material | Polyester Wrapped Steel |

| Shell Material | Polyester |

| Shell Material | RPET/Recycled Polyethylene |