Your Essential Guide to Woodworking Gloves and Safety

Posted by Anthony Webb on Oct 16th 2025

Wood has been used for thousands of years to create items that are both useful and beautiful. Woodworking is defined as the activity or skill of making items from wood. It has helped humanity become more efficient, build substantial structures, and make life generally more comfortable.

The woodworking trade is responsible for cabinet making, furniture making, carving, joinery, carpentry, and woodturning. While the tools have changed somewhat over the years, the ever-enduring woodworking techniques have been passed down for centuries.

You'll need to work safely in the workshop and wear personal protective equipment (PPE) such leather work gloves when handling woodworking materials.

This article will tell you about woodworkers, the tools they use, and the importance of staying safe with those tools.

Woodworkers vs. Carpenters

While one may be thinking that woodworkers and carpenters both build things out of wood and are therefore the same, you would be wrong. While carpenters usually use wood to build structures on a construction site and have to be familiar with various processes and tools, a woodworker deals primarily with machines and tools that prep and shape wood into various uses.

There is also a slight difference between the responsibilities of a woodworker versus those of a carpenter. For example, a woodworker's day may consist of setting up and maintaining automated machines or completing wood products by sanding, staining, and finishing them. A carpenter's responsibilities may include following blueprints or installing wooden structures, frameworks, and fixtures.

Check out this Carpentry construction page for those whose trade involves more carpentry work. Woodworkers may find the information useful, too, as both have similar PPE needs.

Types of Woodworkers, Responsibilities, and The Guild

According to the Bureau of Labor Statistics (BLS), a woodworker manufactures various goods using wood, veneers, or laminates. While the name "woodworker" may bring to mind someone making wooden objects by hand, the job is much higher-tech these days. With the advancement of technology, this trade sets, operates, and tends to equipment like drill presses.

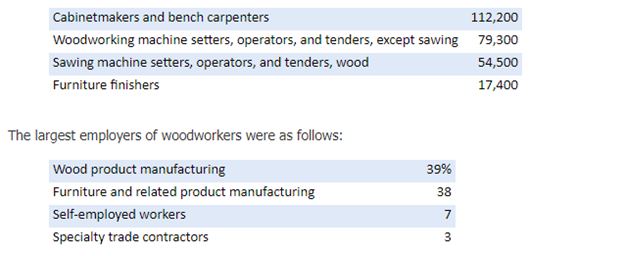

In 2019, there were 263,500 people employed as woodworkers in the U.S. Most of them were employed within cabinetmaking and wood product manufacturing. However, several different woodworking trades are rolled up under the title of "woodworking." Saw machine setters and furniture finishers are classified under this occupation. Here is a breakdown of some of the numbers and percentages in each employment sector:

Bureau of Labor Statistics, U.S. Department of Labor, Occupational Outlook handbook, Woodworkers

While we seem to live in a world filled with plastic and other "disposable" materials, wood still has its place in the modern world, and woodworkers continue to play a significant role in our society. Some of their responsibilities may include:

- Comprehending architectural drawings and blueprints;

- Operating machines, such as saws and sanding machines;

- Safeguarding products to meet industry standards and making the necessary corrections;

- Choosing the appropriate cutting, milling, boring, and sanding tools for the job; and

- Using hand tools to trim pieces or assemble products.

Wood sander, with leather work gloves close by, ready to handle material.

One place woodworkers can go to sharpen their skills is the Woodworkers Guild of America. This organization of woodworking experts has been educating the public with techniques and tips on creating wood projects since 2008. Becoming a member of the guild entitles you to exceptional education opportunities to keep your skills sharp and current.

The Workshop: Essential Tools for Success

Any woodworker will tell you that the first step to success is creating a functional workbench. Workbenches come in all shapes and sizes, but it's essential to find one that will perform the way you need it to and make your job easier.

Some characteristics you'll find familiar on most workbenches include:

- Flat tops with a tool well on one end that can be covered if the wood you're working with is immense.

- Square holes on the front edge drilled at regular intervals for bench dogs and holdfast clamps.

- A cut slot where tools can be put with handles at the ready for easy reach while working.

Some benches may have storage cabinets, and others may be portable for jobs on the go. Make sure you have the right kind of workbench for your specific projects.

Woodworking Bench

Even if you have the best bench for your needs, a project cannot succeed without the proper tools. Some of the necessary tools in a woodworker's toolbox include:

- Drill

- Hammer

- Hand saws

- Planes

- Power saws

- Sanders

- Screw gun

Woodworking Tools

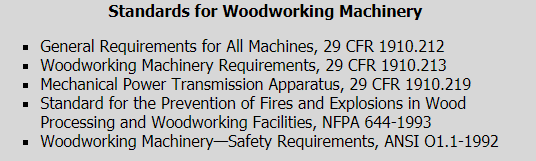

In woodworking, tools need to be resilient and able to work with various woods for different functions. However, just about every device on the workbench can pose a physical threat to the woodworker without proper training or care. A medical study in 2014 showed that over 30,000 injuries occurred annually just from the use of table saws, only one tool in a woodworker's toolbox. This study showed that the most common table saw injuries were hand and finger lacerations resulting in a tendon, nerve, or vascular damage or amputation.

When any tool is being utilized, the woodworker needs to be on guard. The BLS reports that mostcut injuries found across all U.S. industries result from working with tools. And, the number holds true for woodworkers, too. The number one injury woodworkers sustained in 2019 was cuts or lacerations, with the BLS reporting 790 injuries. That is higher than sprains and strains, which might surprise some woodworkers due to the amount of awkward lifting that can occur on the job.

Let's examine the hazards and injuries a little closer.

Hazards and Injuries

![]()

Even the most innocent woodworking project can be laden with possible injuries and hazards. With the tools and materials being used to create the wood project, a woodworker needs to take safety measures. According to the Occupational Safety and Health Administration (OSHA), some of the most common safety and health hazards in woodworking include machine hazards, flying chips and materials, carcinogens like wood dust, fire hazards, and exposure to chemicals such as coatings and finishing.

Wood Dust

During an end-user visit to a cabinet manufacturing facility in 2010; a cabinet manufacturer safety manager told me an awful story. He told me a story of a recently hired employee who had lost his fingers only one week earlier as the result of a horrendous on-the-job injury. Although instructions were given during the orientation to never go near the moving blades of a particular machine while it was in operation, the new employee forgot the warning. In less than a week on the job, he was an amputee. This story's moral to me was that anytime one is working around machines, safety awareness must be at an all-time high. And one verbal warning during an orientation meeting is not sufficient to keep workers safe. Proper signage and wearing appropriate PPE is a must; otherwise, cut injuries will only continue to increase.

The good news is that when proper safety procedures are followed, and appropriate PPE is worn, woodworkers can significantly reduce injury concerns.

Safety in the Shop

The woodshop is not a place where you can hurry through the work or bring a casual attitude to safety. There are too many hazards and tools that can cause severe and lasting injury, and potentially death, to the woodworker. Before tackling your next woodworking project, make sure you follow these basic safety rules to protect yourself:

- Always Wear Safety Equipment

Gloves, especially super-thin cut-resistant gloves, are perfect for woodworkers who handle a lot of different materials. They maintain the sense-of-touch required when feeling wood, yet hands stay protected with gloves made of cut-resistant material.

Also, chemical-resistant and disposable gloves, as shown above, along with safety glasses, are two other ways workers can protect themselves. Safety glasses, especially lined options, protect workers from flying wood chips, dust, and shavings.

Safety glasses keep the wood chips out of your eyes.

Ensure you cover your ears with noise-canceling earphones and your feet with proper footwear. Machinery is loud in a workshop and falling debris can quickly injure a worker's foot.

Tingley's Steel and Safety Toe Shoes and Boots

Although MCR Safety doesn't carry ear protection, we can get you into contact with a distributor who does. Leave us your information, and we'll get one of our 700+ nationwide distributors in touch with you.

2. Wear Appropriate Clothing

You want to make sure the clothing you wear while woodworking isn't so loose that it runs the risk of getting caught in any machinery you are operating. When machines are operating, don't allow your gloved hands to get too near to the moving machinery parts.

You also want to make sure your clothing covers skin areas that might be at risk from flying wood chips or shavings. MCR Safety aprons are a common form of clothing worn by woodworkers to protect the chest and torso area.

39836 Denim Apron

3. Disconnect Power Before Changing Blades

Many woodworking tools offer changeable blades to get your project just right. However, failing to disconnect power to the device before changing a part could cause significant injury should the tool begin working before you're ready.

4. Be Well-Rested and Free of Drugs and Alcohol

Working with dangerous tools can pose severe threats to all people, even those who have not been impacted by alcohol or medication within the last 8 hours. Having a clear mind can help people take the necessary precautions to avoid injuries.

5. Make Sure Your Tools are Sharpened

Dull tools are more dangerous than sharp tools! A blunt tool can make the task even harder to complete, causing a threat to the woodworker's muscles and tendons. Dull tools also run a bigger chance of slipping, kicking back, or binding, causing potentially severe or even life-threatening injuries to the worker.

Keep those tools sharpened!

While this list of safety tips is in no way exhaustive, make sure you are following all safety precautions possible when working with woodworking tools. Do not use any device that you have not been adequately trained on, and stay vigilant at all times.

Band and Miter Saw Safety

By far, the most injuries reported in the woodshop involve saws — usually, a band saw, or a miter saw. Many of these injuries occur when blades are handled and switched out when the machine is turned off but not unplugged.

Band Saw

A band saw uses a rotating metal blade to make precise cuts on metal and wood, while a miter saw is a rotating blade mounted to a hinged frame to make accurate angle cuts. Just by their design, these two types of saws are dangerous and require special care when being used.

Miter Saw

Make sure you are using safety guards for all woodworking tools. Guards provide a barrier between the woodworker and the machines they are operating. Before any PPE is even considered, engineering and administrative controls such as safety guards are necessary to have in place.

Make sure you are adequately trained on any saw or cutting tool before using it. Band saws and miter saws are not tools that you should learn to use through practice. Reading the proper manuals and being trained by someone with experience is the best way to stay safe when using these two tools.

Common Questions

How do I start woodworking?

- While it can seem overwhelming, beginning a woodworking project for the first time is simple. The first place you want to start is by researching what the best tools for beginners are. Look online at blogs of people doing projects similar to what you want to do. We recommend this blog from Love and Renovations to get you started.

How can I dry wood fast for woodworking?

- When your wood comes from a live tree that has recently been cut, you are going to need to dry the wood before you begin your project. Moist wood could make your project warp, crack, or distort when it's finished. Here is our favorite quick and inexpensive way to make sure your wood is completely dry before tackling that project.

What are the top woodworking shows?

- We recommend attending one of the many woodworking shows if you have the chance. While you can find numerous tutorials and videos online, going to a show in person gives you an advantage because you can see the tools and techniques being demonstrated right in front of you. It also allows you to ask questions from people who know the answers.

How to get into woodworking?

- Several things can help you along the way when you are first beginning woodworking. First of all, find a mentor, whether they are in person or online. A go-to person to demonstrate techniques and skills will help you a lot. Also, start small. Don't think you're going to tackle the big impressive projects right away. Like all skills, you'll work your way up to it and build your skills as you go. This video will help guide you through the process of becoming a woodworker.

Protecting Woodworkers

While woodworking is a great hobby or career, it is also one where you need to be outfitted with the knowledge and equipment to keep you safe. If you have any questions about anything covered above, please reach out to us.

We welcome any comments, feedback, or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it’s on the shop floor, an oil rig, or a construction site, we are there providing solutions to workplace hazards. It’s all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, find a distributor, or give us a call at 800-955-6887.