The Ultimate Guide for Machinists: Protecting Hands and Eyes with PPE

Posted by Anthony Webb on Jul 16th 2025

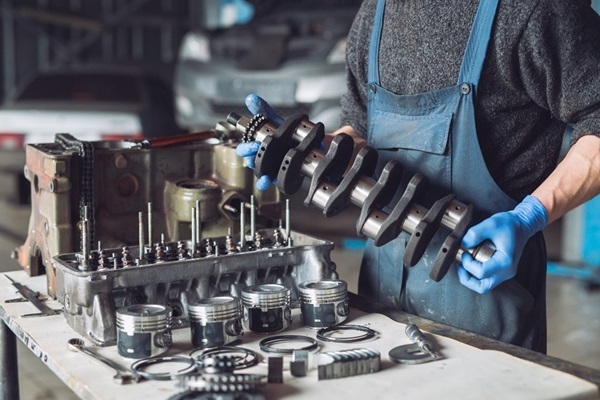

Welcome, Machinists! You are the backbone of the industries that keep the world moving. Machinists are entrusted with the intricate task of crafting precision components and parts, ensuring the very essence of innovation and progress. Without machinists, the manufacturing process would halt, leading to a shortage of critical products and technologies, ultimately disrupting the supply chain.

The machinist drills and cuts into metal all day long, exposing their eyed to flying metal.

As crucial as this profession is, it comes with a several perils, as machinists work in environments fraught with potential hazards, from the risk of injury from heavy machinery to sharp objects and puncture hazards. Those who work the lathe know that a small metal fragment, propelled by the rapid rotation of the workpiece, can dislodge and fly toward the operator's face. Without the protection of safety glasses or goggles, the metal fragment can strike the operator's eye, causing severe injuries such as corneal abrasions, eye infections, or even permanent vision impairment. These risks underscore the critical need for comprehensive safety measures and the proper use of personal protective equipment (PPE) to ensure the well-being of these skilled workers while they keep industries running smoothly.

In this comprehensive article, we'll delve deep into the world of machinists, understanding what they do, the industries they serve, and, most importantly, how to keep them safe. MCR Safety is here to provide essential protective gear like work gloves and safety glasses to safeguard these crucial workers. Let's embark on this journey together, exploring the life of a machinist and the vital role PPE plays in their safety.

What is a Machinist?

What does a machinist do?

Machinists engage in many day-to-day activities, each contributing to the seamless functioning of machines and industries. From setting up and preparing machines to welding, grinding, and performing maintenance, their tasks are as diverse as the products they create. They work with metals, plastics, and other materials, ensuring everything is precise and meets industry standards.

Industries

Machinists are the backbone of several industries, ensuring that machines run smoothly and efficiently. From crafting parts for vehicles to drilling pieces for medical equipment, the precision and accuracy of their work directly impact the reliability and safety of these products. They play a crucial role in the following sectors:

- Fabricated Metal Product Manufacturing: Responsible for crafting metal parts and components used in various applications.

- Machinery Manufacturing: Involved in producing machinery used across different industries.

- Transportation Equipment Manufacturing: Contribute to creating vehicles, from automobiles to airplanes.

Work Activities

In the dynamic and demanding world of machining, machinists engage in various intricate and technical work activities, each demanding high skill and precision. This work is not just about operating machinery; it's about shaping the future one component at a time. The tasks range from the meticulous programming of CNC machines for precision part production to manual machining, where every turn of the handwheel matters. Machinists also engage in detailed assembly and finishing work, ensuring each part meets the exact specifications. Regular maintenance and inspection are equally crucial, as they guarantee the ongoing accuracy and functionality of the machinery.

Here are some of the top machinist activities that require personal protective equipment (PPE):

- Cutting and shaping metal: Precision cutting and shaping metals using machinery.

- Welding and grinding: Joining metal parts through welding and finishing them with grinding.

- Handling hot metals: Dealing with high temperature metals during the manufacturing process.

- Operating machinery: Running machines with rotating parts and mechanisms.

- Cleaning and maintenance: Regularly cleaning and maintaining machines and work areas.

Machinists must employ robust protective measures to safeguard against these eye hazards. Each task, whether cutting and shaping metal, welding, grinding, or handling hot metals, calls for specific types of PPE to protect these skilled professionals. Through this combination of expert craftsmanship and rigorous safety practices, machinists continue to shape our world with precision and care, maintaining the high standards and reliability expected in modern manufacturing.

Common Safety Hazards

In the machining world, safety is not just a guideline but a necessity. As the Occupational Safety and Health Administration (OSHA) points out, machinists face a range of occupational hazards that can lead to severe injuries or impairments if not adequately mitigated. Understanding these risks is key to maintaining a safe and productive work environment, as we will explore in the following sections.

These hazards include:

- Amputations: The risk of losing body parts is heightened when working with heavy machinery. Machinists must be constantly vigilant, as the powerful moving parts of machines can entrap and amputate limbs or fingers if proper safety procedures are not followed.

- Cut Injuries: The workshop environment is rife with sharp objects, metal burrs, and chips, posing a constant threat to fingers and hands. These materials can cause severe lacerations, necessitating cut-resistant gloves and careful handling procedures.

- Crushes, Impact, and Pinch Points: Handling heavy materials and operating large equipment can lead to crush injuries. Machinists must know potential impact points and pinch zones where body parts could be caught between moving or heavy loads.

- Impaired Vision: The risk of eye injuries is significant due to exposure to flying fragments, harmful chemicals, and intense UV light during welding or cutting operations. Safety glasses or face shields are essential to protect against these hazards.

As machinists navigate these hazards, the importance of vigilance and adherence to safety protocols becomes clear. These measures manage the risks of the machining profession, ensuring a safe and efficient workspace for these skilled artisans.

Eye Injury Sources

The eyes are one of the most vulnerable parts of a machinist's body. They are exposed to various hazards in the workshop environment. Each hazard poses a unique risk to ocular health, from the high-velocity debris and filings produced during machining processes to the intense radiant light emitted during welding. Recognizing and understanding these sources of eye injuries is crucial in ensuring the proper protective measures are in place.Flying debris and filings: Small metal fragments and filings generated during machining.

- Metal chips: Metal byproduct resulting from cutting and shaping operations.

- Dust: Airborne dust and particulates in the workshop.

- Molten metals: Splashes of molten metal during welding and cutting.

- Radiant light: Intense light generated during welding, cutting, and brazing.

- Splashing chemicals: Exposure to chemicals used in the machining process.

To safeguard against these eye hazards, machinists must employ robust protective measures. Properly fitted safety glasses, face shields, and other specialized eyewear are not just accessories but essential tools that preserve vision and ensure ongoing safety in the machining profession.

Hand Injury Sources

Machinists' hands are constantly at risk, exposed to various hazards in their daily work. Each activity carries its own risks, from handling sharp objects and tools to dealing with the dangers posed by moving rotary parts and pinch points. Understanding these threats is crucial in selecting appropriate hand protection and maintaining safety in the workshop.

Machinists' hands are exposed to various injury sources, including:

- Sharp objects: Handling sharp-edged workpieces, metal chips, and cutting tools.

- Moving rotary parts: Operating machines with rotating spindles.

- Pinch points: Working near gears, chains, and pulleys.

- Puncture: Metal splinters, chips, and burrs pose puncture hazards

The diverse risks to machinists' hands highlight the necessity of using appropriate hand protection. Selecting suitable right gloves—cut-resistant, puncture-resistant, or otherwise specialized—is critical to a machinist's safety gear, ensuring their hands remain protected while they skillfully perform their work.

Required PPE

Because machining presents many daily hazards, the proper personal protective equipment (PPE) is not just a requirement but a lifeline. From the vital role of safety glasses in shielding eyes from high-velocity debris to the comprehensive protection offered by face shields against sparks and chemicals, each piece of PPE is tailored for specific threats. Gloves, whether disposable, chemical-resistant, cut-resistant, heat-resistant, or puncture-resistant, are equally crucial, offering a tailored defense to keep machinists' hands safe from the varied dangers they encounter.

Personal protective equipment (PPE) is essential for safeguarding machinists. The following PPE products are crucial for their safety.

Eye Protection

Safety glasses, especially foam lined versions like the HK310AF above, shied a machinist’s eyes. Machinists require various forms of eye protection:

- Safety Glasses: Protect the eyes from debris, chips, and radiant light, you'll find all our options here.

- Goggles: Offering additional protection against splashes and spatters, you'll find all our options here.

- Face shields: Shielding the face from hazards like welding sparks and chemicals, you’ll find all our options here.

Gloves

Material handlers moving metal parts require protection from sharp objects, like with the 4850K shown above. Here are additional forms of protection machinists require:

- Disposable Gloves: Protecting the wearer when cleaning and handling materials, you’ll find all our options here.

- Chemical-resistant gloves: Safeguarding against exposure to harsh chemicals, you’ll find all our options here.

- Cut-resistant gloves: Preventing cuts and lacerations from sharp objects, you’ll find all our options here.

- Heat-resistant gloves: Shielding hands from high temperatures, you’ll find all our options here.

- Puncture-resistant gloves: Offering protection from metal splinters and sharp objects, you’ll find all our options here.

With the right combination of PPE, machinists can continue to craft the components that propel industries forward while staying safe and protected from the myriad dangers they face.

Common Questions

Here are answers to some common questions about machinists:

What does a CNC machinist do?

- A CNC machinist operates computer-controlled machines, translating blueprints into precision components and ensuring quality through meticulous programming and monitoring.

How much does a machinist make?

- Salaries for machinists vary depending on location, experience, and industry. On average, they earn competitive wages within the manufacturing sector.

Are machinists in demand?

- Yes, the demand for machinists remains high due to their integral role in manufacturing and industry. Skilled machinists are sought after to ensure precision and quality.

How are machinists changing the world?

- Machinists drive innovation by crafting components for industries like aerospace, automotive, and medical devices, advancing technology, and improving lives.

What does an outside machinist do?

- While their primary role involves working with machines and metal within manufacturing facilities, machinists' expertise can also be valuable in various outside contexts. You’ll find them fabricating parts for equipment repairs, creating custom home fixtures, and maintaining boats and marine equipment.

The Backbone of Industry

As you've learned, Machinists are skilled artisans who craft the components that drive industries forward. In a world where precision and craftsmanship are paramount, machinists stand at the forefront of innovation, turning raw materials into the intricate components that drive our modern existence. These dedicated artisans are the architects of progress, creating everything from engine parts to aerospace components with unmatched expertise.

As they meticulously shape the backbone of industries, MCR Safety remains unwavering in its commitment to providing the highest-quality PPE, such as work gloves and safety glasses, to protect these unsung heroes. As we continue to rely on the expertise of machinists to shape the world around us, let's also commit to keeping them safe with the best protective gear available. If you would like even more information on machinists and the machine shops you’ll find them operating in, check out Machine Shop Industry Page by clicking the below image.

Click on the image below to leave us a comment, question, or any concern.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments.

Whether you're wearing our latest safety glass innovation on a fishing boat or at a construction site,

we provide solutions to workplace hazards. It's all part of our commitment to protect people.

No matter the industry, we have the personal protective equipment you need!

Learn more about MCR Safety by checking out our most recent video. For more information, browse our

website, find a distributor, or give us a call at 800-955-6887.