An Earth-Shattering Look at Excavating and Trench Safety

Posted by Anthony Webb on Jul 2nd 2025

When most people hear the word trench, they most likely think of a trench coat. However, the term goes, literally, much deeper than that of clothing. Trenches are a vital component of civil engineering and are often a significant part of construction projects. One critical industry requiring trenches is the underground utility industry, as they use trenches to install underground infrastructure in the form of gas mains, water mains, communication cables, and pipelines.

Excavator Digging a Trench

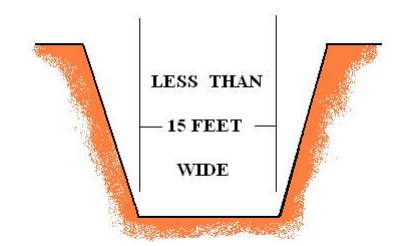

What is a trench? The term “trench,” as it is used in construction and engineering, refers to a long narrow ditch or hole dug into the ground. Different types of trenches are used across construction: some are bell-shaped, others sloped, and many simply straight.

You will often hear the words “excavation” and “trench” used interchangeably; however, there is a difference. Excavations are any manufactured cut, cavity, trench, or depression into the Earth's surface that is formed by earth removal. Trenches are a specific narrow excavation and are deeper than they are wide. And, like all excavations, they are also dangerous, as someone can quickly become trapped in a trench.

This article will explore the world of trench construction and the safety measures and safety gear required when digging. It will also answer some of the common how-to questions related to digging.

Trench Construction

Trenching is a standard excavation method used across most construction projects. In construction, there are numerous reasons to dig a trench. Laying and getting access to services is one of the primary reasons for digging a trench. Trenches can also be used for constructing foundations and building heavy-duty drains, retaining walls, and dams.

As we highlight in our Guide to Construction Equipment article, excavators are the machines often used in the trenching process to remove dirt, rock, and Earth to create a hole in the ground that is usually deeper than it is wide.

Here are some other trench tools needed for digging into the Earth:

- Trench machines – also referred to as trenchers, these machines assist workers in easily removing dirt from a trench

- Trench shovel – allows workers to dig flat-bottomed trenches

- Pick – used to loosen the soil

- Pipe pullers – join concrete and culver pipe

- Drainage spade – penetrates rock and hard soil

- Trenching hoe – drags soils out

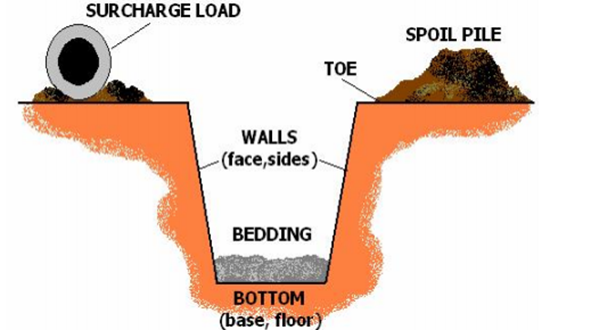

These tools are all used to construct trenches, which feature multiple parts. The image below shows the different parts of a trench formed with the help of these tools.

Trenches are considered a relatively simple construction method, yet they account for OSHA's highest fines. That's because trenching, when done incorrectly, involved numerous hazards and can be a significant safety risk.

Trench Hazards

Digging trenches is one of the most hazardous parts of any construction process, primarily because they collapse without warning. Once the dirt is removed from any location, the surrounding soil becomes unstable. That's when gravity does its part and may cause the surrounding soil to collapse. Having a trench collapse on workers and trap them is the number one concern for anyone operating near a trench. Improper sloping and flooding are two other primary reasons trenches collapse.

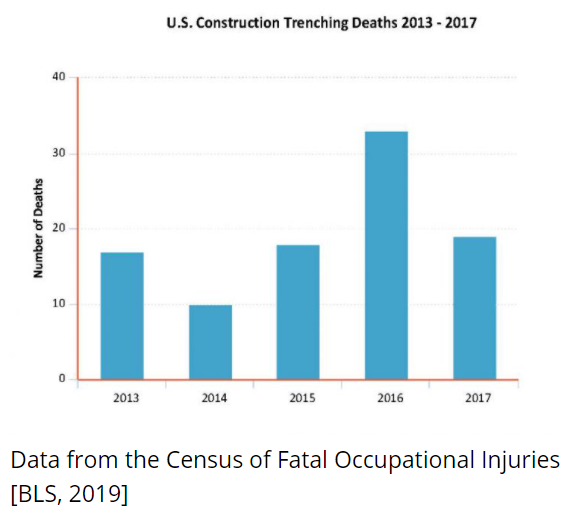

From 2013-2017, 97 trenching deaths occurred in the construction industry, equating to an average of 19 per year. In addition, there are risks for slips, falling objects, and unsafe weather.

Being aware of the hazards associated with trenching is essential! Whether you are working independently on your at-home project or managing a trenching project on a construction site, certain steps must be taken to protect everyone working in, on, or around a trench.

Some of the additional hazards of trenching include:

- Equipment and soil falling in on workers

- Flooding and water accumulation within the trench

- Hazardous atmosphere issues as a result of toxins in the soil

- Buried service lines, including electricity, fuel, water, sewage, and telephone lines

- Materials handling risks

- Unsuitable ladders causing injury

- Excavated soil located too close to the trench

- Heat stress

Before any trenching can begin, it is essential to mitigate as many safety hazards as possible, whether the trench is being dug as part of a company’s construction plan or is being dug by a weekend warrior homeowner working in the yard. Awareness of safety hazards means understanding the soil type, recognizing potential water hazards, and determining current buried lines.

The OSHA trench safety soil classification PDF can be accessed by clicking the above image.

Lastly, each construction site must have someone classified as a competent person responsible for identifying all existing hazards present and considering potential future hazards that might occur. Since trench conditions are constantly changing, these workers pay close attention to whether walls begin to sag or crack, where existing underground power lines are located, and if water begins seeping into the trench. When any of these hazards are present, this person has the authority to stop all operations.

Competent persons also visually analyze soil, test hazardous atmospheres, and assess weather changes. They regularly inspect protective systems, which are highlighted more in our next section.

OSHA Trench Safety

In the U.S., OSHA oversees and develops trench safety guidelines. OSHA's 1926.652 standard highlights all the requirements necessary for protecting employees during excavations and trenching. There is good reason for OSHA overseeing trench safety, as the rate of fatalities caused by trenching is 112% higher than fatality rates for all other types of construction work performed.

One of OSHA's measures with trenches requires companies to employ a protective system to guard workers against cave-ins. The system chosen will depend on the soil conditions, depth and width of the trench, and space needed. Any system that is 20 feet deep or more must be built by a professional engineering firm.

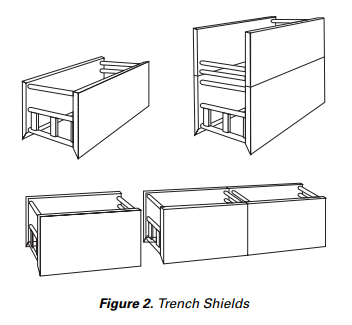

Shoring systems, such as bracing and wall plates, are temporary structures used to assist in avoiding cave-ins. However, OSHA trench box requirements, often referred to as shields, are necessary whenever the digging depth reaches 5 feet or more. The primary aim of a trench box isn't to prevent a cave-in but to alleviate the pressure of the soil on a worker in the event the walls do collapse.

Trench Safety Box

OSHA provides extensive resources for construction site trenching projects. Here are some safety resources you should consider reviewing:

- Trenching and Excavation Safety is an OSHA PDF that informs employers of their essential responsibilities to keeping workers safe from excavation-related injuries.

- The OSHA Fact Sheet serves as a shorter version of the above and is a handy reference guide.

- Trench Safety Checklist - assists the competent person in carrying out daily safety reviews.

Outside of OSHA, the PDF by OSHAcademy covers all the core components of trench safety, from soil conditions to methods that keep workers safe. It's definitely a trench safety manual you'll want to check out!

Lastly, visit the National Trench Safety website for a plethora of resources related to trenching. They are the go-to experts for training around trenching Safety and all the products necessary while trenching.

YouTube Excavation & Trench Safety Resources

As always, training is key to understanding safety, and you can never have too much training. YouTube is another excellent resource for anyone interested in learning, especially around the topic of trenching projects! If you learn best from watching people conduct excavation projects, then YouTube is the place for you. Here are some videos to consider watching:

- Excavation & Trenching Safety – is an excellent training video that introduces the viewer to all facets of trench safety.

- Safety Toolbox Talks from NAHBTV - provides a shorter video than the one above, highlighting the core components of trench safety.

- Shoring Safety –teaches the core components of shoring and OSHA compliance.

Safety is such an essential part of any construction project, and SafetyVideos.com provides yet another overview of the safety guidelines for trenching.

PPE and Safety Equipment

When you're working in the trenches, it helps when you have personal protection equipment (PPE) designed to keep you safe on the job. Here are some PPE styles you’ll want to consider having for trench work:

- Safety glasses – trench workers are surrounded by dirt and rock. Dirt that falls six feet can hit a worker with force equivalent to a pick-up truck going 35 mph! You don't want your eyes to be subjected to these conditions without some level of protection. Our online safety glasses catalog will point you in the direction of the 700+ styles of safety glasses we sell. Our new Memphis series offers brand-new styles that match low-cost with high-fashion and exceptional protection.

- Hi-vis gear – helps heavy equipment operators notice people working in and around trenches. This form of protection is required by anyone working on an excavation site close to the roadway, as cars travel by workers at high rates of speed. Our online hi-vis catalog shows all the options available, from safety vests to hi-vis rain gear.

- Work gloves – construction workers handle many tools, are constantly moving materials, and handle abrasive gear when moving equipment. As we've identified above, a trench box must be a part of any trench, and they require workers to use their hands and tools when installing. Our entire online work glove catalog is a helpful resource to find the right gloves for your needs. Below are a couple of our favorites we know construction workers utilize.

- Steel toe rain boots – falling objects, materials, and equipment are a constant concern for those working in a trench. Keeping your feet guarded is an absolute requirement. You'll want to check our online foot protection catalog to see all of the styles we offer.

Common Questions

How to dig a trench?

The Easy Digging website provides a free trenching guide to help individuals understand how to dig a trench. Many homeowners perform trenching manually rather than renting a trencher. That's because most at-home projects simply don't justify the expense of a rental trencher.

Many companies will rent trenching equipment from places like United Rentals. And, users at home will also rent trenching equipment, most likely from local hardware stores such as Lowes and Home Depot. Besides the most common practice of purchasing or renting a trenching machine, there are four critical tools used for trenching: drainage spades, trenching shovels, clean-out scoops, and trenching hoes. One of the biggest challenges in digging a trench is effectively cleaning out the bottom of any debris and Earth that falls from the sides.

If you need to dig a deep trench, one popular and effective strategy is to dig one shallow but wide trench, and then dig a secondary trench at the bottom of the first. The secondary trench will be deeper but narrower. As with any trench, you should follow the same safety guidelines.

How to dig a drainage trench?

Installing drainage is a common reason for trench-digging, as drains assist in removing water that tends to pool in places like driveways and loading docks. Having a trench drain detail, which provides the framework for installation, is vital before any digging begins.

In short, you dig the trench, place underlying material at the base of the trench, install the drain pipe, cover the pipe, and then cover the trench itself. However, to help guide those who need more details, these two guides provide clear instructions for how to dig drainage trenching: How to Dig a Trench and How to Dig a Trench for Drainage [10 Ridiculously Simple Steps].

Here are some critical takeaways from these guides:

- Calculate the appropriate slope

- Confirm the safety of the area where you will be digging

- Make a solid plan before digging.

Protecting Diggers with PPE

Excavating and trenching are necessary components of any construction site. Unfortunately, hazards are plentiful when excavating, and trenching and safety measures are key whenever construction begins. One of the most foundational safety measures is PPE. We hope the above article has helped further your understanding of safety measures needed during trenching and the gear you need to protect your body.

Click this image to leave us comments, questions, or any concerns.

We welcome any comments, feedback, or suggestions for how we can best protect people at work.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's digging trenches on a construction site or working on the shop floor, we are there providing solutions to workplace hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, find a distributor, or give us a call at 800-955-6887.