Warehouse Safety Guidelines and Rules

Posted by Anthony Webb on Oct 10th 2025

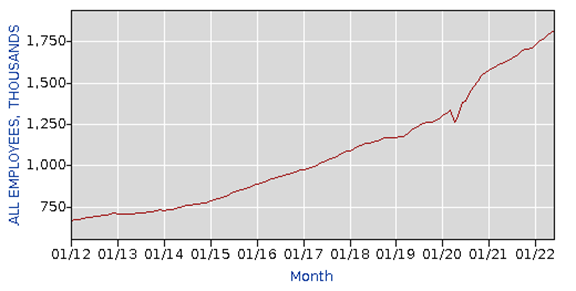

Industrial warehouses are large buildings designed to store things like raw materials and finished inventory before those items are sold or used. In total, over 19,000 independent warehousing facilities are operating across the U.S., and that number doesn’t include the warehouses privately owned by companies to store their goods. As of 2021, more than 1,766,600 people work in the private warehousing industry, and that number continues to rise.

Employee growth in warehouses has increased over the past decade due to e-commerce.

Warehouses are classified as general warehousing, refrigerated warehousing, or farm product warehousing. Each has different needs with regards to protecting workers from workplace hazards. Across these different types of warehouses, there are similar types of employees. The most frequent occupations in warehouses are order fillers, laborers who move materials, and packagers. All these workers use their hands, meaning work gloves are essential protection. And, in the case of those working in the refrigerated sector, insulated gloves are a must.

Besides hand protection, workers wear numerous other types of personal protective equipment (PPE), so it’s critical to understand the most common warehouse hazards and how to minimize risks. This article will discuss the most common OSHA violations found in warehouses, review the rules and guidelines that are essential to the safety of warehouse workers, and highlight PPE to help keep warehouse workers safe on the job.

Top OSHA Violations

![]()

The Bureau of Labor Statistics (BLS) shows that the warehousing industry, represented by NAICS code 493, experiences 4.8 total recordable injuries for every 100 employees. That is 39% higher than the 2.9 injury average across all industries. Each year, OSHA provides information regarding the most common warehouse safety violations that often contribute to such a high rate of injuries.

Here are the top 10 safety issues at a warehouse, based on OSHA recorded violations:

- Forklifts – hazards often occur when equipment or unsecured products strike workers. Forklift operators who don’t have the proper training increase the likelihood of injury from forklift turnover and driving mishaps. Standard 19100178 addresses this violation.

- Hazard Communication – violations exist when companies fail to provide written communication for employees around hazardous chemicals. Workers must know what potentially dangerous chemicals exist and the best protection methods when working around these hazards. Standard 19101200 addresses this violation.

- Electrical Wiring – dangers are all over commercial buildings in the form of raceways, conductors, busways, and cable assemblies. Any incorrect method of wiring poses a potential hazard. Standard 19100305 addresses this violation.

- Electrical Systems – when proper grounding and circuiting are not in place or safety barriers are not guarding electrical systems, workplace hazards are common. Standard 1910301 addresses this violation.

- Guarding Opening – violations exist when workers are exposed to unguarded staring openings or wall openings. They can also exist around open pits, tanks, vats, and ditches.Standard 19100037 addresses this violation.

- Multiple Exits – are required in the event of fire or smoke. At least two exits must be well constructed and far apart.Standard 19100037 addresses this violation.

- Mechanical Power Transmission – violations result when improper operations exist concerning mechanical components that transmit energy, such as moving belts found on conveyors.Workers can quickly become caught in such systems if guards are not in place.Standard 1910145 addresses this violation.

- Respiratory Protection – violations occur when workers are exposed to harmful airborne particles and toxins without proper PPE. Standard 19100134 addresses this violation.

- Lockout/Tagout – violations occur when hazardous energy is not adequately controlled. Our article Learn About Lockout Tagout provides insight on this subject. Standard 1910147 addresses this violation.

- Portable Fire Extinguishers – violations occur when extinguishers are unavailable, fully charged, or easily located.Standard19100157 addresses this violation.

OSHA identified the above hazards when they wrote their Worker Safety Series Warehousing Guide in 2014. Based on 2020 and 2021 citations, some others have moved up the list: material handling with 22 citations, OSHA General Duty Clause with 15 citations, and fall protection with five citations.

OSHA Guidance

It’s essential to be current on the latest safety regulations to protect both warehouse workers and owners. Though the above violations can lead to severe injury, steep fines, and legal penalties, there is guidance offered by OSHA to combat hazards and ensure a safer workplace. The online warehousing website lists hazards and recommended solutions to all warehouse-related safety concerns.

OSHA’s Pocket Guide to warehouse worker safety is a helpful resource that identifies a range of warehouse hazards and provides solutions to reduce risk and increase safety. It also provides checklists for warehouse owners to ensure they do everything possible to protect their employees.

Here are some more OSHA resources that can aid operational staff:

Safety Rules and Online Resources

What are the safety rules for a warehouse? In some ways, this is a complex question since safety rules vary depending on the types of operations, equipment, and materials used in a particular warehouse. However, some general rules should be followed by workers in any warehouse. Knowing these rules can help you assess your warehouse safety currently and guide you in making the proper adjustments to increase safety.

Here are some general tips anyone overseeing warehouse safety should follow:

- Keep floors clean and free of slip and trip hazards.

- Loading docks with the potential for a four-foot fall or more should be chained or roped off.

- Provide workers with proper ergonomic training, especially around proper lifting techniques. More on ergonomics is found in our article Educating Workers about Ergonomics.

- For storage, place heavier loads on lower or middle shelves. Also, provide overhead guards to protect forklift operators from falling objects.

- Maintain three points of contact when climbing ladders. More information on ladder safety can be found here.

- Prohibit stunt driving and horseplay in the warehouse.

- Ensure an adequate ventilation system exists to disperse dangerous gases.

- Install safeguarding equipment between conveyors and workers, ensuring clothing, body parts, and hair cannot become entangled in the machinery.

- Provide easily accessible warehouse safety procedures for all, such as fire safety procedures in an emergency.

In addition to the OSHA online resources above, here are some of our favorite online warehouse safety guidelines and sources we recommend you check out:

Signs

As we highlight in our article Safety First: The Top 10 Safety Signs, workplace signs are critical in keeping people informed and aware of potential hazards. Many warehouses don’t have the proper signs to mitigate workers' risk during specific operations. This might be as simple as a stop sign or a label for the fire extinguisher to more significant warning signs for dangerous areas or hazardous materials.

Having the right signs in the right areas of your warehouse helps reduce confusion and dangerous mistakes. Signs increase worker safety, especially ones that identify warehouse aisles and rows, guide forklift traffic, specify rack weight limits, and caution workers about potential hazards.

Here are some of the signs found in almost all warehouses:

- Forklift warning signs

- Pallet storage area identification

- Shipping and receiving area identification

- Exit signs

- First aid signs

- “Caution: Wet Floor” signs

Because signs are vital, OSHA is very particular about the rules regarding signage. OSHA’s complete guidelines give detailed information about signs' required symbols, colors, and printing specifications.

Safety Knives for Warehouses

Knives are standard tools used in warehouse shipping and receiving, so it’s crucial to have a blade appropriate for a given task. The wrong blade or a dull blade reduces efficiency and increases the risk of injury. Although OSHA doesn’t have set regulations regarding knives, employers must follow best practices, including identifying the correct cutting tool for a particular job, promoting the proper grip and cutting motion, and educating about blade replacement and maintenance.

In addition to using the correct knife, workers must understand correct cutting techniques. Because knives pose safety concerns, it makes sense for workers to protect their hands by wearing cut-resistant gloves. You can find all our cut-resistant glove solutions in our online cut-resistant glove catalog. Click the image below to go there now and check out the options we know users will want to consider in warehouse environments.

Safety Clothing and Safety Vests

Are reflective vests useful in a warehouse? Yes. Every year, roughly 100 employees die while operating or working around forklifts. These accidents often result from workers not being seen.

Reflective vests enhance the visibility of a worker, which is especially important in avoiding forklift traffic accidents. Since safety vests are bright and reflective, they reduce the risk of a forklift or other vehicle colliding with an unseen worker. Vests are relatively inexpensive and comfortable to wear, which makes them a direct investment in the safety of your warehouse employees.

Click the image above to check out all our safety vests, including General Purpose, Class 2, and Class 3 options.

We also stock vests fitted for women.

Warehouse Gloves

OSHA mandates that companies give all warehouse employees access to the correct PPE. Hi-vis safety vests and cut-resistant gloves are only the beginning of keeping workers protected. OSHA recommends that warehouse operations managers perform a site hazard assessment to determine what personal protective equipment (PPE) must be worn based on the hazards present and educate warehouse employees on the PPE required.

Below are some additional PPE products MCR Safety offers that a warehouse worker will find helpful.

Thin Gloves For Warehouse Work

Workers often sort packages, and coated and/or dotted gloves offer added grip. See our wide range of general-purpose gloves.

Workers wear our dotted work glove styles at warehouses all over the country. They provide users with what is known as the "Grab Factor," making it easier to grab boxes.

Freezer Gloves

Refrigerated cold storage facilities store temperature-controlled goods. Our new 9674IN glove, made with merino wool, provides warmth without sacrificing dexterity. And it’s made with FDA-approved accepted materials, so you are ok when touching food products. For additional insulated worker gloves, click the image below.

Thinsulate gloves for cold warehouse work are top sellers.

Box Handler Glove

The PD1902 box handler glove, featuring A4 cut resistance, is designed to keep hands protected from sharp objects. It also features a red tire tread pattern grip, excellent for handling boxes.

Cooling Gear and Cooling Towels

Heat affects warehouse workers who perform work in hot temperatures. Our cooling gear lineup is worn by workers across the country during the hot summer months.

Safety Goggles and Chemical Protection

OSHA identifies eye and face protection as necessary PPE for charging stations when handling lead-acid batteries. MCR Safety specializes in producing a variety of safety glasses and goggles.

OSHA identifies the PPE required when handling chemicals or cleaning up spills. Our chemical protection page highlights all the chemical-resistant gloves we offer, along with safety goggles and garments designed to protect against chemical hazards.

Safety Glasses

In refrigerated environments, workers need safety glasses that won’t fog. Our Max 6 styles feature the most advanced anti-fog coating we offer.

Common Questions

How can a warehouse ensure the safety of its workers?

- Several important safety guidelines exist to protect warehouse workers, including using the proper safety equipment, such as hard hats and safety goggles, and eliminating potential floor hazards.

How can paint improve warehouse safety?

- Paint can outline safe walking paths, improve floor traction, create effective warning signs, denote specific areas and types of materials, and more.

What are other ways to improve warehouse safety?

- Helpful tips to improve warehouse safety include installing a camera inside the warehouse to alert workers when a trailer has arrived and installing safety lights around the loading dock. For additional safety tips, check out our safety rules section above.

Protecting Warehouse Workers

MCR Safety’s warehouse resides outside Memphis, TN. It has over 500,000 square feet of storage space stocked with personal protective equipment (PPE) ready to ship out to distributors and users across the United States. From experience, we know that even a well-organized warehouse can be dangerous, so protective measures are always taken to ensure individual safety. And at MCR Safety, your safety is our top priority, which is why we’ve provided insight into overall warehouse safety. For any of the PPE highlighted above, we hope you plan on allowing us to protect you!

Click the below image to leave us comments, questions, or any concerns.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's sorting packages on a conveyer belt, moving materials with a forklift, or working at a construction site, we are there providing solutions to workplace hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, find a distributor, or give us a call at 800-955-6887.