How to Treat Cement Burns

Posted by Anthony Webb on Dec 5th 2024

The United States produced 83.5 million tons of Portland cement in 2017, and imported even more. The nearly 180,000 American concrete workers are a critical part of the economy, but the potential hazards of the work are significant.

Aside from crush injuries and silica dust hazards, such as silicosis, cement itself is also a source of potential danger and is not to be underestimated.

How Cement Burns Occur

Dry cement is abrasive, but no more so than many similar materials. It’s wet cement that can cause chemical burns on the skin. When water is added to cement, relatively harmless calcium oxide becomes calcium hydroxide, which has a pH of 12-14.

While momentary contact with unbroken skin is unlikely to cause harm (after all, children have been putting handprints in wet concrete for ages), extended contact makes it more likely that a burn might occur. This slow-forming injury means that, by the time symptoms appear, many people no longer associate the injury with wet cement. This leads to misdiagnosis and mistreatment that can make the problem worse.

Prevention

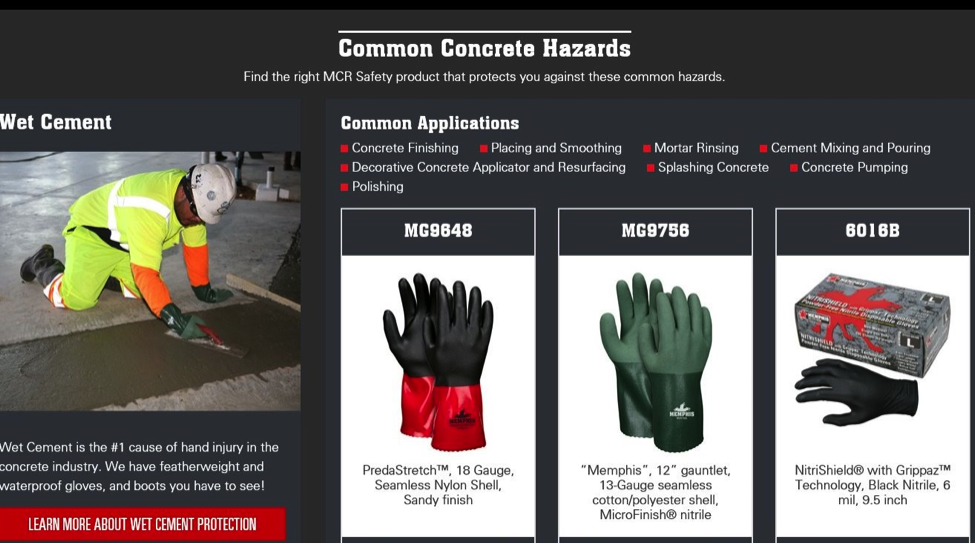

Ironically, the use of protective clothing that isn’t specifically intended to be used around concrete makes it more likely that a chemical burn will occur, thanks in large part to improper use. Wet concrete can become trapped inside gloves, boots, and sleeves, leaving it to sit unnoticed next to the skin for minutes or hours.

Watches and jewelry are also potential sources of danger. Taking safety precautions as an individual and instituting safety policies as a manager can help to reduce the number of caustic burns from wet cement. Here are some tips:

- Wear appropriate protective gear. Long sleeves and pants, gloves, boots, knee pads, eyewear, etc. A study on cement burn cases, admitted to the national burns unit at St. James Hospital in Dublin, Ireland, found that all the

cases involved burns to the hands, arms, feet and legs.

Be sure to check out our website Concrete Protection section on our website, highlighting all the gear you will need for encountering wet cement.

- Get or provide appropriate safety training. A 1997 study showed 35% of apprentice concrete masons suffered from concrete burns. It’s critical that everyone, both new and experienced, knows how to take appropriate safety measures.

- Wash hands before putting on gloves. Putting gloves on over residue is just as harmful as not wearing gloves at all.

- Remove clothing splattered in concrete and wash the affected area. Immediately, not in an hour. Keep an eye on any skin to see if a burn or other reaction develops.

- Take care while removing protective clothing, washing hands afterwards. Store protective clothes away from other clothes and tools that are in everyday use.

- Read the Safety Data Sheet (SDS), formerly known as the material safety data sheet. This goes not just for concrete, but any material you’re working with. Don’t trust secondhand information about safety, see the manufacturer’s warnings with your own eyes.

How to Tell If You Have a Concrete Burn

If you’ve been working with concrete and are developing any kind of skin-related symptoms, assume you’ve been burned. It’s much better to plan for the worst and discover it’s just heat rash than to ignore it and find yourself with a serious burn that has gone untreated far too long.

Symptoms of a concrete burn include:

- Redness

- Itching

- Dryness

- Blisters

- Scabs

- Pain

These symptoms appear and worsen over time. If the only symptoms you see at first are dryness and a bit of a pink color, there is no reason to assume that the burn will stop there, even if you have removed the offending chemical from the skin.

The MG9648 is our most comfortable and lightweight waterproof glove offered!

Perfect for wet cement protection!

First Aid

- If you notice that a burn is forming and you have not already done so, remove any clothing, jewelry, or protective gear.

- Brush off any dry concrete before washing. (Adding water will only create more wet concrete, compounding the problem.)

- Wash the area with cold running water for 20 minutes. Both OSHA and the National Precast Association recommend adding some vinegar or other acidic substance to the water, which can help stop the burn. Here is what both say: OSHA: Consider using a mildly acidic solution such as diluted vinegar or a buffering solution to neutralize caustic residues of cement on the skin.

National Precast Association: To help neutralize the alkalinity, add vinegar, citrus, or a buffer to the water.

- Take the person to be evaluated by a medical professional. Be sure to tell the doctors or nurses involved, repeating as often as necessary, that this is a cement burn. This is critical, cement burns can look just like a burn caused by heat, but the treatments are different. Delaying the correct treatment can mean the difference between a mild burn and a severe one.

- Call 911 immediately if the burn is more than 3 inches across, very deep, or covers the hands, feet, face, groin, or a major joint.

Although it might seem like a good idea, do not use lotions or creams to soothe the area. Many contain ingredients like lanolin and petroleum jelly that might seal the cement to the skin.

Treatment

Next steps will depend on the spread and the depth of the burn. The medical staff will wash the burn, even if you’ve already taken this step. Antibiotics may be given to reduce the chance of infection, and the burn will likely be dressed with bandages.

If the burns are serious, surgery may be required, including debridement (removing dead tissue) and grafting (transplanting healthy tissue). If the burn covers a part of the body requiring dexterity, such as the hands or knees, it’s especially important to receive ongoing treatment to ensure that scar tissue doesn’t limit future range of motion.

On-Site First Aid Kit

- A source of clean water. Running water onsite is ideal, but several gallons per worker will also do.

- pH neutral soap without any softening agents, scents, or alcohol.

- Clean towels.

- pH indicating strips.

- NSAIDs or other over the counter painkillers.

- Extra protective gear, in case one set becomes contaminated and unwearable.

MCR Safety Is Committed to Keeping You Protected

Be sure to check out our concrete section where we breakdown the personal protection equipment (PPE) workers need when facing a multitude of concrete hazards, one of these being wet cement.

We highly recommend that any employer looking for safety gear education around their specific working applications should register for The MCR Safety 360° Protection Program. We will provide you with a thorough assessment of your operations and make safety gear recommendations.

Whether you need gloves, glasses, or garments, we have you covered! We Protect People!