A Meaningful Review of Metal Stamping and Safety

Posted by Anthony Webb on Oct 27th 2025

Let's face it, many times working professionals get thrown to the wolves when it comes to the work performed in business, whether that’s the safety professionals keeping others safe or the physical workers making things. That’s why, at MCR Safety, we believe in keeping you informed about how our products fit into various industries, such as metal stamping.

Workers in this industry are exposed to sharp corners and jagged edges, which means their arms and hands need to be protected. They also come into contact with solvents and flying particles. All of these scenarios require workers to be protected with quality safety gear.

This article will explore the world of metal stamping, focused primarily within the automotive industry, the hazards involved, and the personal protective equipment workers should consider wearing to stay protected.

What is Metal Stamping?

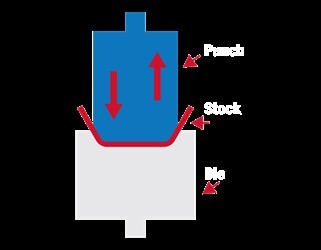

Stamping metal is the process by which metal is cut and formed into a desired shape or profile by a stamping die, whose cutting and forming parts are made of particular types of steel. Within the automotive industry, metal stamping is the fastest method available for producing the vast numbers of parts to create automotive vehicles.

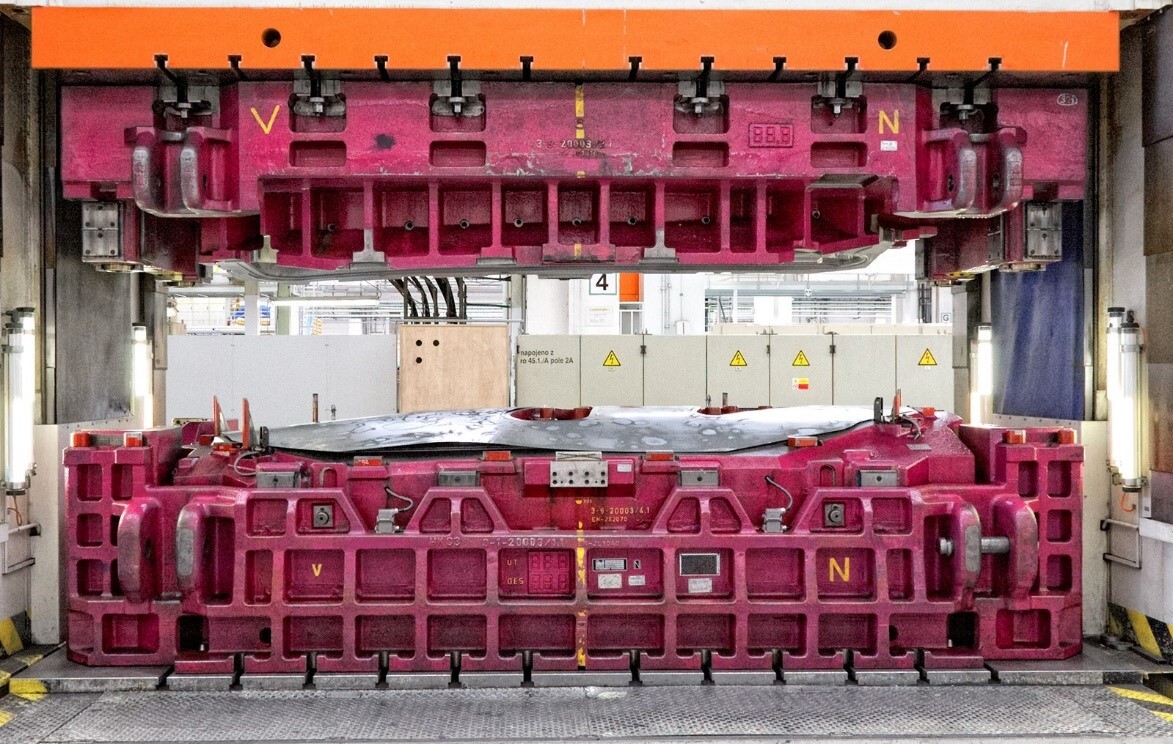

Metal in the stamping press before stamping occurs. The dies mounted on the press help cut and form

metal into different shapes, whether a truck’s door or a car’s hood.

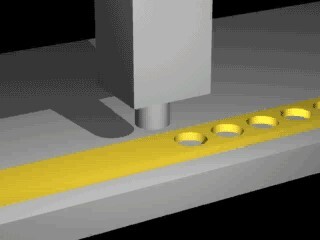

This image shows metal after stamping occurs. Sharp metal is everywhere, meaning cut

protection is essential.

Keeping with the theme of metal stamping, let’s press on and examine where PPE plays its part in the overall process. You can use our left-hand navigation to jump directly to our PPE section or continue reading more about stamping processes and automotive metal stamping.

Stamping Processes

Stamping is a “cold-form” operation. Heat is not used during the process; however, friction generates heat as the metal is cut and formed, so metal often becomes very hot when it exits the die.

There are different stamping processes, depending on what final product is desired:

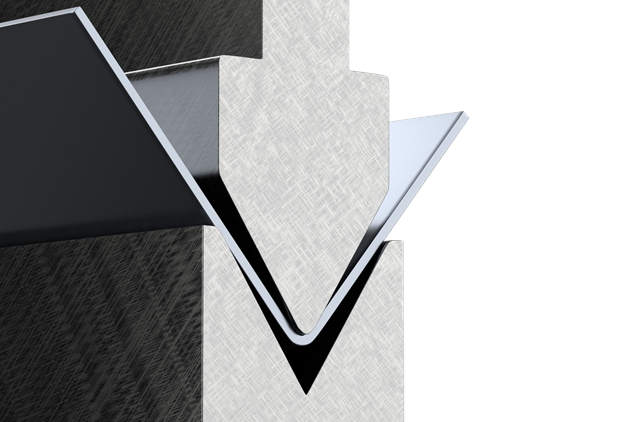

- Bending: Metal is bent into specific shapes. Force is applied to created simple curved surfaces.

Equipment that bends metal: power presses, press brakes, and tubing benders.

- Blanking: Cutting shapes from large pieces of metal.

- Coining: Letters, numbers, or mages are imprinted on the metal’s surface. (This is how coins are made, thus the name.)

- Drawing: Metal is forced against a die and is stretched into a three-dimensional object, usually a complex shape. It is the most common method for making auto body parts.

- Piercing: Indentations are made on the surface of the metal; the metal is not cut all the way through. Instead, a cavity is left on the metal's surface.

- Punching: The cut shape is discarded, and the surrounding metal is used. Both blanking and punching can be done at once.

Equipment that punches metal: power presses and ironworkers.

Automotive Stamping

Metal stamping is one of the first steps in the automobile production process. Stamping is essential to the fabrication of automobiles because of the large number of different-sized steel parts that are assembled into finished vehicles and the ability to stamp and replicate a high volume of identical parts. A car body may contain more than 1,500 stampings, in addition to large parts, including the doors, floor, chassis, and roof.

Stamped Automotive Parts

As mentioned above, many automotive parts are made by a process known as drawing. In drawing, a flat piece of sheet metal is placed on the forming die. It is held in place via a compressive force exerted by a blank holder, which controls the sliding of the metal sheet during the drawing process.

A punching tool then moves down to the piece, causing it to deform. The metal flows into the die cavity to create the final shape, typically hollow and open on one side. The term “deep drawing” refers to the shapes produced by this method, as they often have depths that exceed their diameter.

Stamping Process

Automotive Stamping Machine

We know many of you are visual learners, so here is a look at metal stamping’s role in vehicle manufacturing plants:

- Metal blanks made. The steel is turned into metal blanks.

Metal Blanks

- Tool-die makers get to work. Workers prep the press, and stamping begins.

Prepping the Press

- Press machine stamps out metal components. Workers have to handle stamped parts and feed the blanks into the machines to make different components. Examples include rear frames, panels, bumpers, and floor and side panels.

Stamping Metal Parts

- Stamped metal is detached. Workers move the stamped metal parts to production, loading them onto welding robots.

The highest cut protection should be worn when handling stamped metal.

Cut-resistant gloves are essential PPE needing worn throughout all stages of working around the metal. However, its importance can't be understated when workers must handle rough-edged stamped metal and move to other work stations where sharp metal is present.

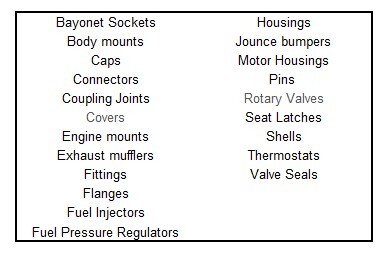

Stamped Metal Products

There are thousands of stamped parts used in automobiles, and we can’t go into detail about them all. There are stampings for automotive chassis, seating stamping, stamped brackets, and a laundry list of other metal components stamped out to fit vehicles. Here is a list of some of the parts that regularly get stamped.

Metal Stamping Car Parts

Precision metal stamping is used to create large quantities of automotive parts.

Applications Performed

Stamping Press Line

Workers perform a variety of tasks during the stamping process and when forming metal, including:

- Bending and forming metal sheets to desired shapes

Bending Metal

- Checking and inspecting parts

- Cutting and separating metal

Stamped metal is sharp and is a leading cause of injury when separating.

- Handling metal panels and body structures

ANSI A9 cut-resistant gloves offer the highest level of cut protection for handling metal.

- Grabbing and handling sharp metal parts formed from the presses

- Lifting stamped parts into place on the welding line

- Moving and transferring stamped parts to welding cells

Moving stamped metal is another step in the process requiring tremendous caution.

- Operating machine-presses

Hazards and Injuries

Bending Metal

Metal stamping is hazardous work. There are 4.5 million reported injuries in the metal manufacturing industry each year. In 2016, OSHA cited one metal stamping company for nine serious and two other-than-serious safety violations. Workers can get injured at every step of the stamping process.

When you examine injuries within the automotive industry, most of them occur around the stamped metal itself. We’ve touched on it several times above: parts with rough, sharp edges will quickly lacerate a worker’s hands or arms.

Injuries typically occur when workers take stamped pieces off the machine, move stamped parts, and then transfer them to welding cells for frame assembly.

Workers in metal stamping are at risk when:

- Material handling: The edges of sheet metal may be abrasive and razor-sharp, so even the most careful worker is at risk for cuts if they’re not wearing the proper protection.

Stamped metal is found throughout the automotive industry, even in body shops. You don’t take chances

with sharp metal, period. MCR Safety’s cut-resistant sleeves, made with DuPont™ Kevlar®, are the ticket to fewer injuries.

- Sharp objects: Sheet metal workers are in constant contact with some of the world’s sharpest materials. Workers are punching, cutting, bending, and shaping metal.

- Cuts and crush: workers can be cut by sharp metal edges and have their hands or arms crushed by objects. There is also a concern when cutting materials with snips.

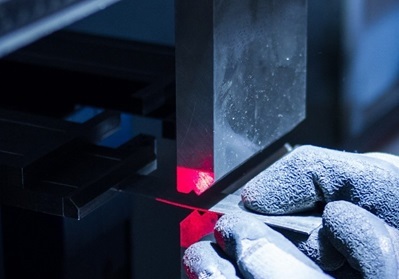

- Impaired vision: Workers who handle sheet metal are potentially exposed to flying metal fragments, particles, and projectiles. Also, robot inspection in automotive stamping is a time when workers will want to make sure their eyes are protected.

- Puncture: Metal splinters, small metal chips, and burrs are found all over sheet metal. They can easily puncture workers’ skin.

Keep in mind; the automotive stamping dies have to be repaired, too. There is 13,000 tool and die makers working in

parts manufacturing and at risk from many of the same hazards as those involved in the stamping process: burrs, sharp metal, and flying metal fragments.

Personal Protective Equipment

Stamping requires that workers wear the best cut protection available. Here are two new

products that we want to make sure you see:

MCR Safety Cut Pro™ (92735N)

15 Gauge Hypermax™ Shell

Nitrile Coated Palm and Fingers

This advanced glove features a 15-gauge plaited black Hypermax™ and steel shell. The plaiting provides additional comfort from steel fibers that help reinforce the glove’s strength. From a strength standpoint, the 92735N scores a “top of the chart” ANSI Cut A9 and ANSI Puncture 4. The reinforced thumb crotch provides extended use in a high-stress area. The black color also hides dirt and grease to give the user a perceived desire to wear the gloves longer.

MCR Safety Cut Pro™ (92743BP)

13 Gauge Hypermax™ Shell

Bi-polymer Coated Palm and Fingertips

This advanced glove offers a seamless salt & pepper Hypermax™ shell that supplies cut-, tear-, and abrasion resistance. It also offers good dexterity and is comfortable and easy to wear. The black foam nitrile/water-based PU-coated palm and fingertips provide a durable grip and

hide dirt, grit, and grime. With high cut and abrasion scores, this glove keeps coming back for more.

Arms need protected from jagged metal.

Goggles and safety glasses are important when unstrapping coiled stock.

Die specialists and equipment maintenance operators need protection from solvents and cutting fluids.

Check our chemical matrix for each glove's chemical performance.

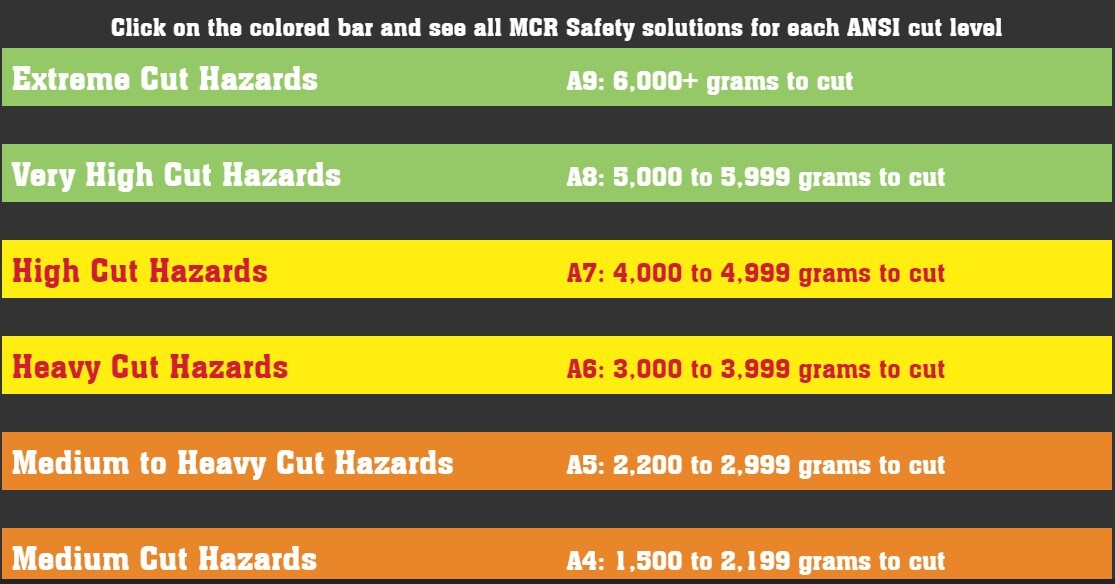

You should also check out our Glove Cut Protection page. We explain the American National Standards Institute’s ANSI/ISEA 105-2016 cut-resistance standard and provide a beneficial sorting tool for choosing different levels of cut-resistant gloves, from ANSI A2 to A9. All metal stamping workers should consider wearing at least A7 cut protection and above.

Click the image to view MCR Safety's Cut Resistant Glove Blog!

Our cut-resistant catalog is your next step for all cut-resistant options, including several matrices that showcase the sleeves that stamping metal workers wear.

In addition, to help prevent injury to employees, employers should guard or eliminate machine parts, functions, or processes that may cause injury. They should affix guards to the machine where possible and secure them elsewhere if attachment to the machine is impossible. It is essential to make sure the guard is not a hazard in itself.

Other Helpful Resources

We've covered a lot, but here are some other are resources if you want to understand more about metal stamping safety:

- Metal Stamping Operations – Safety Rules

- Quality Management Information in Automotive Stamping Process

- Metal Stamping Safety RulesMetal Stamping Safety Handbook

Also, we want to stress that MCR Safety gloves are not for use around moving equipment.

Safety Is Committed to Excellence

As Aristotle once said, “We are what we repeatedly do. Excellence is not an act, but a habit.” When it comes to working safely, this could never be more of a true statement. Repeatedly showing workers how to operate stamping equipment properly and requiring them to wear the correct metal stamping PPE ensures operational and safety excellence.

MCR Safety pursues excellence every day across all corners of the company. Whether at our manufacturing facilities, customer call center, distribution center, or the specialists in the field are performing 360° product assessments, we all are committed to keeping workers safe!

Click the above image to leave us comments, questions, or any concerns.

For over 45 years, MCR Safety has proven to be a world leader in gloves, glasses, and garments. Whether it's wearing premium EVA rain boots while working on the shop floor, an oil rig, or a construction site, we are there providing solutions to workplace hazards. It's all part of our commitment to protect people.

No matter your industry, we have the personal protective equipment you need.

Learn more about MCR Safety by checking out our most recent video. For more information, browse our website, find a distributor, or give us a call at 800-955-6887.