In a 2013 eyewear survey MCR Safety conducted with end-users, 60% of all participants surveyed listed anti-fogging as the #1 most important buying decision when selecting safety glasses. While fog is not going to hurt your eyes, it will hurt your visibility and project a distorted view, which can cause serious accidents and injuries. Many times, fogging is what causes workers to take off their glasses or permanently stop wearing their safety glasses altogether. Both scenarios put the worker at risk, as the impact from flying projectiles or chemical splashes can damage the eyes within seconds. All of this also adds up to a company being potentially exposed to increased medical claims, lost productivity, and lost profits. For both the company and the worker, wearing the correct safety glasses just makes good sense.

Accident Analysis and Prevention published results in 2009 from a focus group centered around the “[f]actors influencing worker use of personal protective eyewear”. Out of seven groups queried, 100% considered fogging to be a significant factor for vision-related issues. So, it’s not only MCR Safety’s studies that indicate fogging is a concern. One user is noted as saying,

"We took a poll at our company about why people don’t wear [their safety glasses], and fogging up is one of the bigger problems because we work outside all year round. So on the cold days of winter when you put them on and you start to heat up, they immediately fog up; on rainy days, if it’s raining, you get rain water all over your glasses and you can’t see out of them. So people tend not to wear them under those conditions".

The last thing you want is a pair of fogged safety glasses on this cold day

The solution many people use is anti-fog wipes, like our LFT Fog Buster wipes. The only downside to these is that the wipes need to be used and reapplied every time your glasses fog up. While wiping your lenses is a perfectly respectable solution once or twice, if you’re regularly encountering major differences in temperature or wearing a respirator on a daily basis, it’s not a long-term fix. Moreover, if you are responsible for a number of people, multiply the several minutes it takes to de-fog glasses by the number of times fogging occurs by the number of employees, and you are losing a significant amount of productivity time. And that is if nobody gets hurt when they are unable to see. And that’s a big if.

Enter anti-fog technology. By wearing anti-fog safety glasses, workers stop removing eyewear and remain protected from workplace eye hazards. At MCR Safety, we’ve been working on developing technologies to help workers solve the age-old problem of fogged safety glasses! Below we highlight four total technologies we’ve developed for our glasses. Before we get to that, we have some educational information to highlight. Below is a little additional information on why glasses fog and an overview of the industries where fogging is common.

Why do they fog?

Fogging takes place because of the phase change of matter. If a worker quickly changes from cold to hot, glasses can become fogged. This is because warm air holds more moisture. As the cold lens cools down the warm, moisture-laden air, condensation forms on the lenses of the safety glasses. The lenses cause a phase change as the warm vapor touches them and turns into a liquid.

Combine the above with human exertion, like a laborer grinding away at daily tasks, and you’ve got an environment ripe for fogged safety glasses. As body heat increases, perspiration occurs, and moisture once again increases the likelihood of fogging.

Here are several reasons why glasses fog:

Ambient Heat

Thermal energy of the surrounding environment, like that of a foundry, heats the air and condensation easily forms against the cooler temperature of the lenses

Quick-rising Temperatures

Whenever sudden shifts in temperatures occur, such as walking outside into a warm summer day from a cool building, there is a high probability of fogging. Essentially, anyone moving from indoor tasks to outdoor tasks faces potential fogging issues.

Workers who find themselves working in multiple environments throughout the day will, at some point, face a possibility of their glasses fogging.

Increased Humidity

Moisture in the air increases the likelihood of fogged safety glasses.

Wearing a Respirator

Oftentimes, when wearing a mask or respirator, water vapor from one’s exhaled breath is aimed directly at glasses, thus fogging the lenses.

Outdoor Work

Strenuous activity in high heat leads to condensation. When you’re dripping in sweat, the last thing you want is nonfunctioning PPE.

Wearing Full-body Gear

When a worker is in full gear, heat and moisture are often prevented from escaping, building up condensation within the gear. To combat this scenario, we’ve made headgear and face shields with advanced anti-fog coatings.

Industries

The Bureau of Labor Statistics (BLS) reports that nearly three out of every five injured workers were not wearing safety glasses when the injury-causing accident occurred. One reason workers choose not to wear safety glasses is due to fogging. Here are some of the many occupations that require anti-fog safety glasses:

Construction Workers

Construction workers are exposed to prolonged high heat and humid conditions, which can lead to fogging.

Food Industry Workers

Food Industry workers are constantly going in and out of frigid coolers. Both frozen food plants and manufacturing facilities require anti-fog glasses.

First Responders

EMS first responders must be able to quickly transition from vehicles to accident scenes with the ability to clearly see what they’re doing.

Utility Workers

Utility workers are exposed to prolonged high heat and humid conditions.

Airport Workers

Airport workers sometimes employ de-icing machines for airplanes, which can quickly fog up eyewear due to the spraying of heated water. All employees who work outside at an airport are exposed to the elements.

Chemical Processing

Chemical processing requires daily interaction with harmful chemicals. Eyewear must always be worn, but it doesn’t help if it fogs up.

Industrial Workers

Industrial plant workers are often working in hot temperatures. Whether a concrete plant, energy plant, or bottling plant, high temperatures cause workers to sweat, creating additional moisture.

Industrial Plumbers

Industrial plumbers plumbers find themselves surrounded by hot steam coming off pipes from time to time. Safety glasses are a must.

Laboratory Personnel

Laboratory personnel require fog-resistant goggles and safety glasses. Walking in and out of a lab exposes workers to different environments.

Welders

Welders wear anti-fog glasses under their primary welding helmet. This makes it easier to have safety glasses close by when chipping off the slag.

Miners

Mining involves working underground in cool conditions, while often times moving into hot work area conditions.

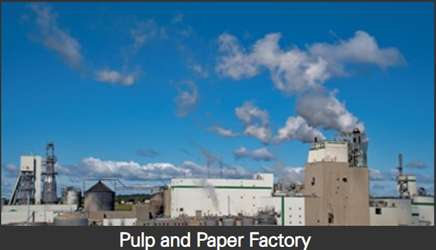

Pulp and Paper Workers

Pulp and paper workers face steam from the paper drying process and all that humidity is quick to fog up glasses.

Mill Workers

Hot foundries, hot manufacturing, and steel mills emit a lot of heat. The high ambient temperatures increase the probability of fogged safety glasses.

Keep in mind, we’ve only listed the top industries where we know fogging is a concern. Any industry can be impacted by conditions that cause safety glasses to become fogged.

Anti-Fog Technology

Anti-fog treatments applied to safety glasses are essentially chemicals that prevent the condensation of water. Originally developed by NASA during Project Gemini to keep spacesuit visors fog-free (and it’s hard to imagine any climate more demanding than the vacuum of space), anti-fog agents prevent condensation from forming. Here is what NASA stated in their Apollo Experience report -

"Develop a system that prevents helmet fogging during heavy exertion. Although the lunar walker did not experience fogging of their visor while on the moon and used anti-fogging wipe to prevent it, its possible occurrence could be catastrophic. An example for potential adverse effects due to visor fogging was the Apollo 11 mission. Crew members remained in their suits during recovery operations for quarantine concerns. The visor fogged once the CM was opened to the humid, warm South Pacific air, completely obscuring their vision. One crewmember became very concerned during transfer from the CM to the rescue basket, as he was unable to clear the visor to see where he was going. Whether it was due to exterior fogging due to the cooler visor causing condensation to occur on the visor or that there was no anti-fog wipe available or used is unclear. The implications on the lunar surface are obvious. Visor fogging needs to be eliminated as a concern, especially if a contingency situation occurs where the crewmember is physically exerting himself or herself for extended periods of time."

Official Apollo 11 Research Recommendations

Project Gemini Spacecraft, June 5, 1966

Today, anti-fogging coatings are used in SCUBA diving masks, ski goggles, and, yes, even safety glasses!

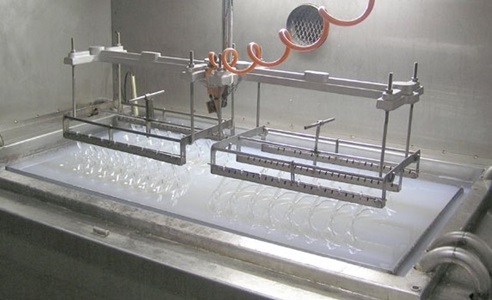

Anti-fog coatings work to varying degrees, and our MAX6 technology is some of the best. It offers six times the anti-fog performance of standard fog-resistant technology. Where standard glasses can take minutes to clear and many popular anti-fog glasses can take 60 seconds or more, glasses with MAX6 technology clear in 10 seconds or less, if they fog up at all. MAX6 technology chemically bonds and incorporates the anti-fogging coating into the lens during manufacturing, so there is no need to worry about reapplying the coating to maintain its anti-fogging properties. And, unlike many of our competitors, MCR Safety directly manufactures all its eyewear. This ensures the product we produce is quality controlled with coatings you can trust!

All MAX anti-fog coatings are chemically bonded to the safety lens

As we mentioned above, with 60% of people citing fogging as a major buying factor, we’ve continued to expand our anti-fog lineup with the most advanced coatings. Click on any of the four different anti-fog technologies for more information. We provide a quick snapshot of each after the logos below.

Standard Anti-Fog Testimonial

"They seem to resist fogging better than any of the other safety goggles I have. They fit over my glasses just fine."

Anti-Fog Technology Snapshot

It’s important to note, before describing any of the technology, that the only PPE that can achieve 100% no-fogging requires a source of airflow. Any claim that suggests otherwise should be cautiously considered.

Standard AF

Anti-Fog coating have been used on MCR Safety glasses for decades now, on some of our most popular styles: Bearkat safety glasses, Checklite safety glasses and Law safety glasses. This standard AF coating offers basic fog protection by incorporating chemicals into the lens that prevents condensation of water, which resembles fog. MCR Safety’s styles utilized this one technology until 2014, when a major advancement in anti-fog technology occurred... Max6 technology. Today, even more advanced coatings are entering the market, which will soon replace this coating all together.

UV-AF

UV cured coated safety glasses provide 3X greater anti-fog performance!

MAX 6

Glasses coated with MAX6 technology, in most cases, will not fog. In extreme conditions some fogging may occur, but they will defog up to 6X faster than standard AF styles.

MAX 36

3X greater scratch-resistant coating on the outside lens, 6X greater anti-fog on the inside. These glasses offer the perfect blend for those seeking both features. We have them in polarized styles, too!

Over the next 3-5 years, we will be upgrading all our AF styles to UV-AF, at no additional charge. It’s a part of our ongoing commitment to protect workers from hazardous workplace conditions.

Technology Examples

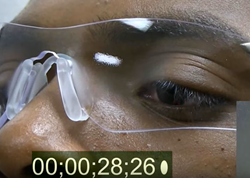

Hearing is one thing but seeing is believing. So, we’ve got some examples of a Standard AF and a MAX6 style operating in a freezer cooler. Check out the full video here.

Standard AF Coating

Using the terminology “anti-fog” doesn’t mean that a glass will not fog at all. It means that the glass is intended to immediately start defogging once fogging occurs. Within thirty seconds, MCR Safety’s T4110AF defog.

MAX6 Anti-Fog

In a freezer setting, you can see that the safety glass barely shows any signs of fogging. Within 5 seconds, there is absolutely nothing present on the glass. Hence the name: 6X greater performance than standard AF styles.

MAX 36

Max 36 Testimonial

"I wanted to give some feedback on the Dominator DM3 Glasses DM1337BDC. They are absolutely awesome! They have even been on a trip to Mexico, they have been the absolute best safety glasses/sunglasses I have ever had, including expensive brands like Oakley. The two best things I love about them, of course, is the anti-fogging, it is truly amazing. Being in humid climates they have never fogged over on me, the only thing I had to do was wipe the sweat and water off of them! Also, the anti-scratch coating is just awesome!"

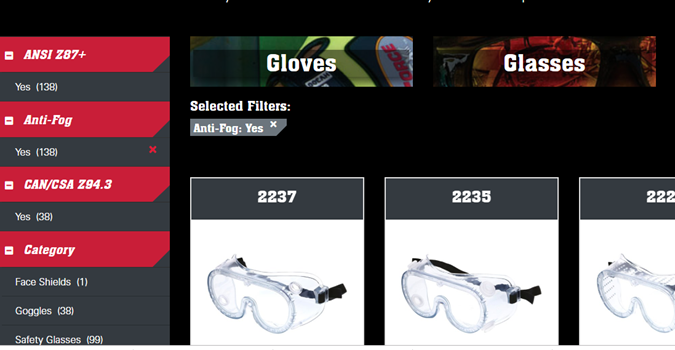

Online Eyewear Catalog

MCR Safety has been manufacturing safety glasses since the early 1980s. We have a variety of anti-fog styles from which to select. For a look at our entire line-up of anti-fog safety glasses, just click the image below and it will take you directly to our eyewear catalog. From there, you can use the left-hand side to filter multiple combinations. Under the image, we’ve shown an example of the additional filtering.

Example of additional filtering: Anti-Fog Goggles. If you’re working in a lab, you’re going to want to check out our MAX6 goggles! Our filtering will allow you to quickly highlight both attributes. You might also be interested in this new Max 6 transitional lens mentioned next!

Photochromic Lens

Nobody likes it when their glasses fog up! It’s a frustrating experience for sure, especially when you’re surrounded by hazards that can cause injuries within seconds. If you can prevent fogging from occurring in the first place, why would you not?

Let us help you keep the fog off of your safety glasses and keep you safe on the job!