In our modern world, sheet metal is considered one of the most versatile and thinnest metals. With its versatility, companies use sheet metal for constructing buildings and manufacturing many other metal products. Examples include manufacturing stove pipes, light tanks, ducts used in HVAC systems, and countless other metal products. Sheet Metal workers are those that make all these products come into existence.

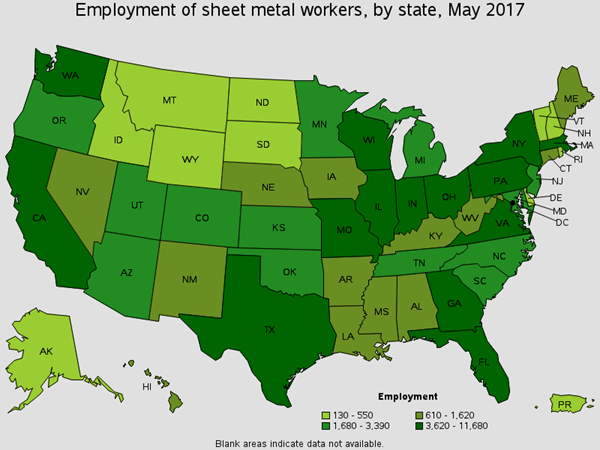

Here is a look at the US states employing the most sheet metal workers:

Sheet metalworkers will often be fabricating metal or installing sheet metal. In most cases, these workers should be wearing highly cut resistant gloves, like the 9366BK, the N9878BNF and the 9178NF. Since sheet metal can have extremely sharp edges and corners, common injuries are cuts and lacerations, so high ANSI cut rated gloves are recommended.

N9878BNF

The Bureau of Labor Statistics (BLS) reports there were 138,900 sheet metalworkers in 2016. Here are many of the activities performed by sheet metal workers:

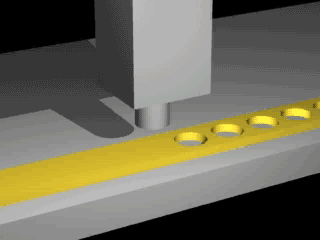

Drilling Holes for Screws

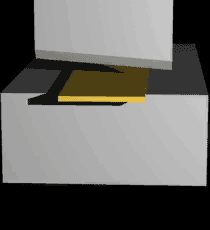

Worker Handling Metal Sheet and Roll Forming

Fabrications shops are where sheet metalworkers fabricate sheet metal. These shops are a little different from machine shops, in the fact that workers actually fabricate parts out of sheet metal, rather than only machine metal. Like machine shops though, a worker has to be constantly on guard against flying metal and particles. Workers in fabrication shops form, cut, bend and straighten out sheet metals. Here is some of the equipment found in a fabrication shop:

Click on an equipment heading to expand and learn more

Power is applied to a slide in order to draw or stamp metal or other materials. Hazards occur as the stock metal material is inserted, held, and withdrawn by hand.

Equipment that bends metal - Power Presses, Press Brakes and Tubing Benders

Power is applied to a slide for the purpose of blanking, drawing, or stamping metal. Hazards occur as the stock metal material is inserted, held, and withdrawn by hand.

Equipment that punches metal: Power Presses and Iron Workers

Applying power to a slide or knife in order to trim or shear metal. Hazards occur as the stock metal material is inserted, held, and withdrawn by hand.

Equipment that shears metal - Mechanically Powered Shears, Hydraulically Powered Shears and Pneumatically Powered Shears

Lastly, Vibranium is the hardest metal found on the planet, so you can imagine it might be a little sharp. Technically, Valerian steel is the strongest steel encountered by metalworkers. Well, this would all be true if we lived in the world of Black Panther or Game of Thrones. These metals are only fictional metal, yet there is no shortage of sharp metal encountered by metal workers every day. Whether you are in a metal fabrication shop or installing sheet metal, there are numerous safety hazards faced. We have got you covered with some of the most rugged and dependable PPE available to workers. We cover many of the hazards you will face when working with sheet metal below.

Find the right MCR Safety product that protects you against these common hazards.

Working around any material can be dangerous. When it comes to sheet metal, you don’t want to take any chances. Check out our high dexterity, high cut resistance and back-of-hand protection.

Learn More About Cut and Crush ProtectionCommon Applications

Sheet metal can be hot and rough when handling.

Common Applications

Working around sheet metals exposes you to flying fragments, particles and projectiles.

Learn More About Impaired Vision ProtectionCommon Applications

Sheet metal itself can be razor sharp, causing deep and serious cuts. Never run your fingers along raw metal edges. For peace of mind, you're going to need high quality work gloves.

Learn More About Material Handling ProtectionCommon Applications

Metal splinters, small metal chips and burrs are found all over sheet metal. Might be smart to wear high rated ANSI puncture gloves.

Learn More About Puncture ProtectionCommon Applications

Sheet metal workers are in constant contact with some of the world’s sharpest materials. Workers are punching, cutting, bending and shaping metal.

Learn More About Sharp Objects ProtectionCommon Applications

The saying goes, "You don't know what you don't know". Let our 360 team help you know more abut PPE.

Learn More About Lack of Safety Knowledge Protection Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.