"I like to think of myself as an oilman. As an oilman, I hope that you'll forgive just good old fashioned plain-speaking."

Let us speak plainly here. Drilling for oil comes with many risks.

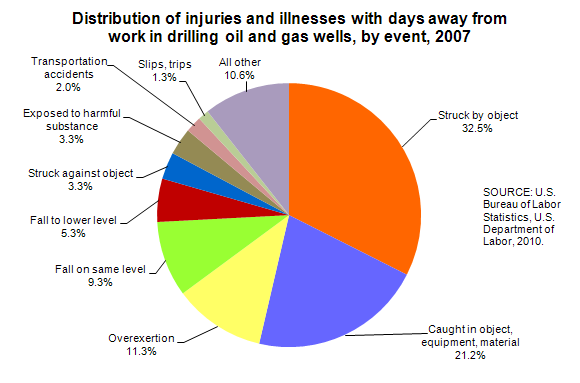

The two highest ranked injuries shown above paved the way to today’s modern impact protection. We will discuss more about it below and other hazards that cause many of the above injuries. First, though, let’s discuss a little more about the history of drilling and the industry itself.

Riggers face no shortage of dangerous work

The industry, commonly referred to as Upstream, finds and produces crude oil and natural gas.

One of the first documented records of petroleum products is in the Bible, with the construction of Noah’s Ark.

"Make yourself an ark of cypress wood; make rooms in it and coat it with pitch inside and out"Pitch: More of a solid rather than liquid derived from petroleum, is used to waterproof barrels, buckets and seal the hulls of boats.

The world’s first oil wells were drilled in Szechuan, China. The Chinese drilled for oil and then used bamboo pipelines for transporting natural gas. The dark, sticky material they extracted was used primarily as a source of fuel.

Whales were hunted for oil and widely used in oil lamps, margarine and soap. However, with whale populations decreasing, costs rising, and better lubricating oil needed for industrial machinery, new sources were required.

Along with whale oil, other oils were used: linseed oil, vegetable oil and surface level oil springs.

Colonel Edwin Drake discovered the first underground oil reservoir near Titusville, Pennsylvania, after drilling a well only 69 feet deep into the “Oil Spring. He was initially looking for ways to improve the yield of “Rock Oil” discovered. His drilling yielded 1600 gallons of oil, instead of 400 gallons from surface level oil springs.This discovery paved the way to today’s modern Oil and Gas economy.

Rock Formations

Oil and gas production starts with first identifying and determining where to drill. To accomplish this, Geologists and geophysicists conduct geological surveys. They study the seismic activities of rock formations to determine well sites, called a wildcat well.

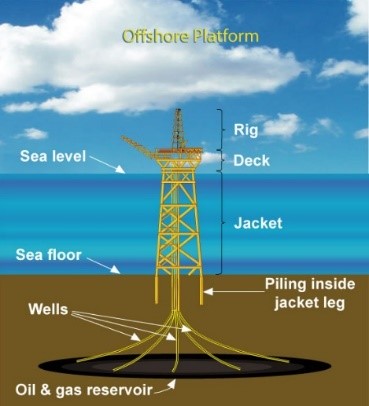

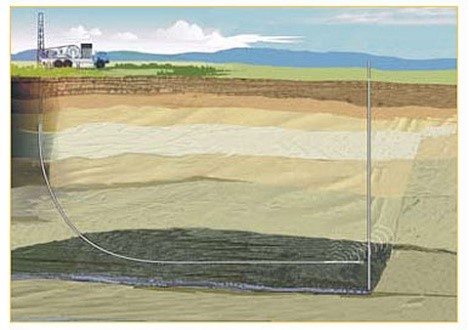

In this phase, companies physically create the borehole in the ground. Drilling occurs either Onshore or Offshore. Here is a brief description of each type of drilling:

Derrick

Includes all of the drilling sites located on dry land. It involves drilling deep holes under the earth's surface, incorporating the derrick, along with other associated machinery.

Platform for Offshore Drilling

Involves drilling hundreds of feet below water, allowing companies to access oil deposits underneath the ocean floor. Ensco, FMC Technologies and Transocean are three of the largest offshore oil companies.

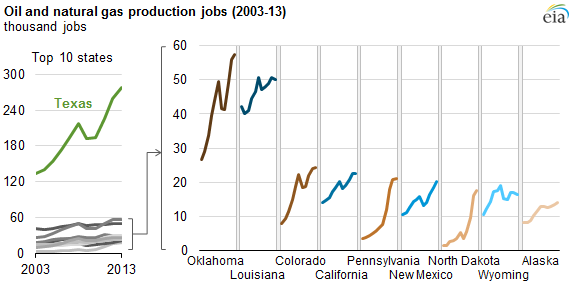

Involves efficiently extracting and bringing hydrocarbons to the surface. It also involves treating and making them available for market. Simply stated, where there is production, there are jobs. Here is a look at the states employing the most workers over a 10-year period.

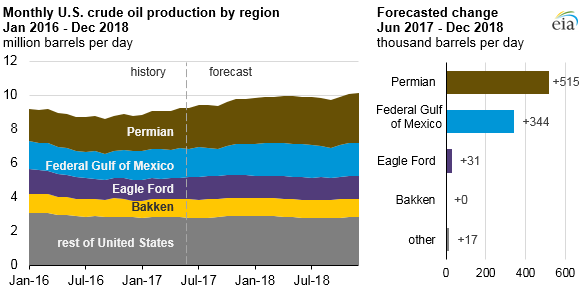

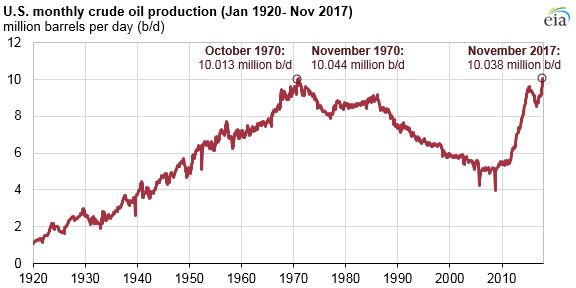

The above three oil production phases are known as traditional methods, however over the past decade unconventional methods have taken off. Here are some examples:

Occurs when a well is drilled vertically and then horizontally drilled. The well runs parallel to the formation containing the oil or gas.

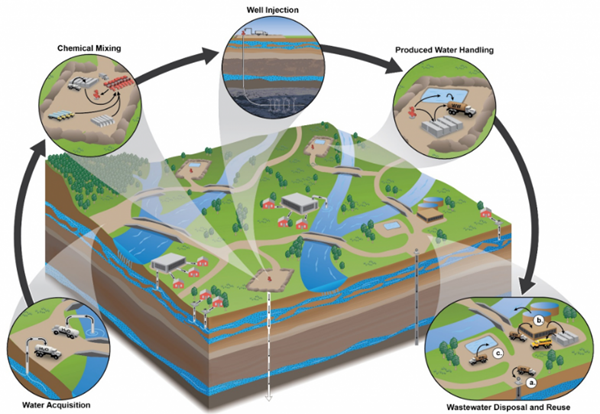

Hydraulic Fracturing Stages

Process of injecting water, chemicals and sand into wells at extremely high pressures. Fractures in the surrounding rock allow hydrocarbons to escape.

The exploration, drilling and production sub-industry involves three types of companies.

Here is a quick look at the key companies from each:

These companies, known as Integrated Oil Companies or IOCs, operate in multiple segments of the oil industry. BP, Chevron, Exxon Mobil, and Shell are high profile companies operating as Majors.

| Company | Total Employees |

|---|---|

| Shell | 92,000 |

| Exxon Mobil | 69,600 |

| BP | 74,000 |

| Chevron | 51,900 |

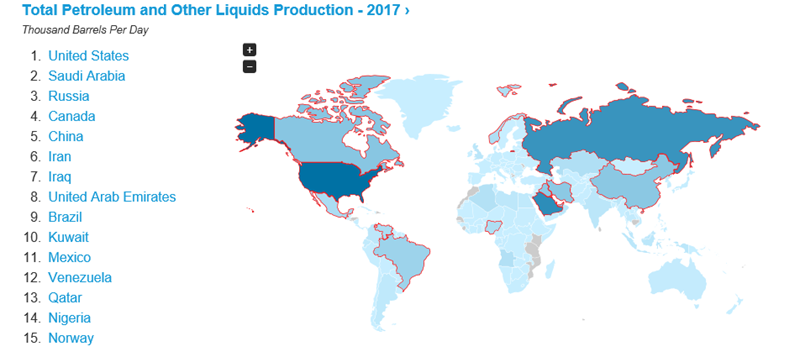

National Oil Companies are owned and managed by governments around the world. When looking at global Oil and Gas enterprises, these companies produce the largest # of oil barrels.

| Company | Total Employees |

|---|---|

| China National Petroleum Corp | 1,636,000 |

| Gazprom (Russia) | 462,400 |

| Pemex (Mexico) | 138,000 |

| PDVSA (Venezuela) | 70,000 |

| Saudi Aramco | 65,000 |

| NIOC (Iran) | 41,000 |

| Kuwait Petroleum (Kuwait) | 39,000 |

Kuwait, Iran, Saudi Arabia, and Venezuela are a part of OPEC, Organization of the Petroleum Exporting Countries, an intergovernmental organization of 15 nations headquartered in Vienna. OPEC production decisions for output significantly impact worldwide Oil prices.

These companies are only concerned with exploring, finding and producing oil.

| Company | Total Employees |

|---|---|

| Anadarko | 4,400 |

| Apache | 3,356 |

| Chesapeake | 2,900 |

| Continental | 1,000 |

Here are the occupations found working at the companies mentioned above: (Click an occupation to expand and learn more)

Perform tasks involving physical labor at construction sites. There are roughly around 21,000 of these workers found in Exploration, Drilling and Production. You will find these workers using hand tools, repairing drilling equipment, and transporting materials. Helper, Laborer, Post Framer, and Construction Worker.

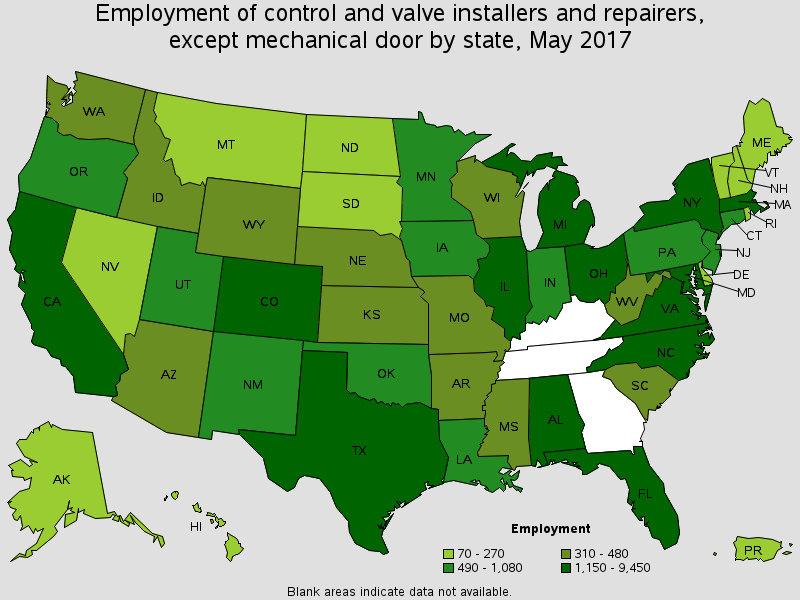

Install, repair, and maintain mechanical regulating and controlling devices and other mechanical governors. There are a little over 500 of these workers in Exploration, Drilling and Production. You will find these workers repairing mechanical control devices, lubricating mechanical parts, and installing electric meters. Common job titles for this worker are Control Valve Technician, Service Technician, and Valve Technician.

Employement of Control and Valve Installers and Repairers

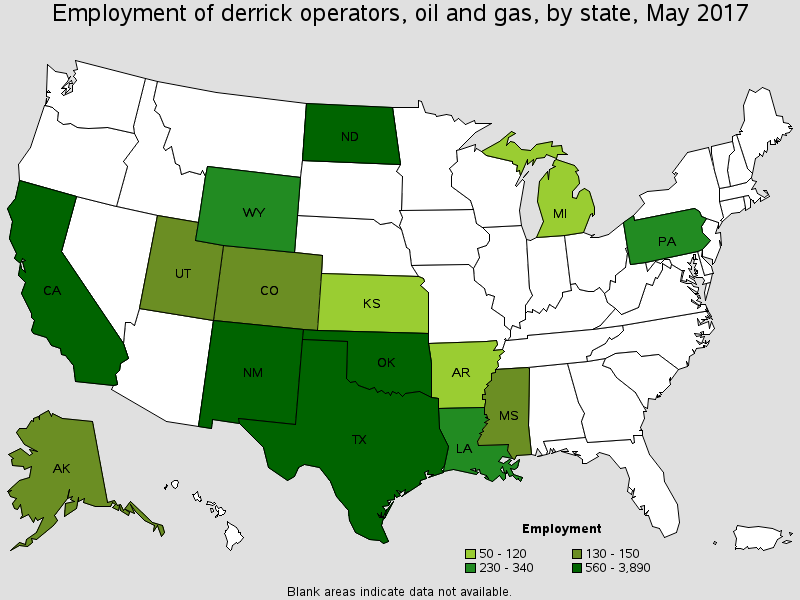

Rig derrick equipment and operate pumps to circulate mud through drill holes. There are around 9,200 of this occupation employed in Exploration, Drilling and Production. You will find these workers inspecting derricks, repairing mud tanks, and setting crown blocks to posts at the top of derricks. Common job titles for this occupation are Derrick Hand, Derrick Worker and Floor Hand.

Employement of Derrick, Rotary Drill, and Service Unit Operators

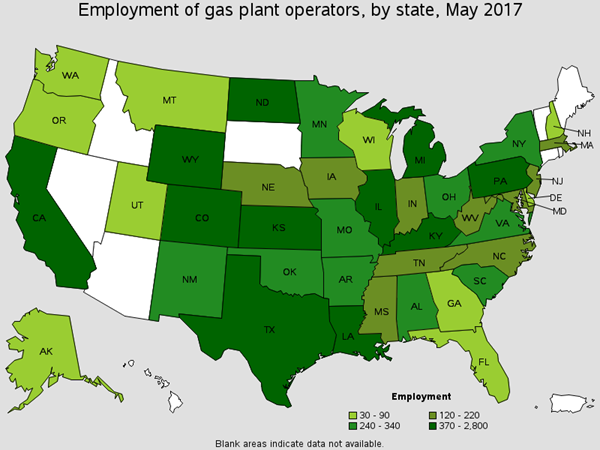

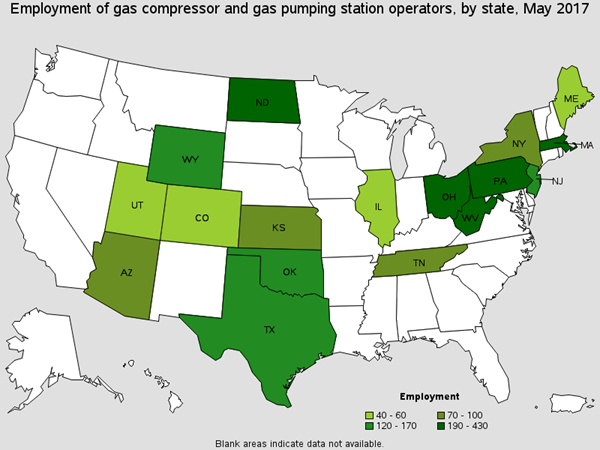

Distribute or process gas by controlling compressors to maintain specified pressures on main pipelines. There are over 1,000 of these workers in Exploration, Drilling and Production. You will find this worker operating plant equipment, monitoring flammable products, and controlling compressors. Job titlees for this worker are Gas Controller and Plant Operator.

Employement of Gas Plant Operators

Gather samples such as rock, mud and soil. There are around 2,800 of these workers in Exploration, Drilling and Production. You will find these workers monitoring well exploration activities and analyzing drill cuttings. Common job titles are Data Technician and Technician.

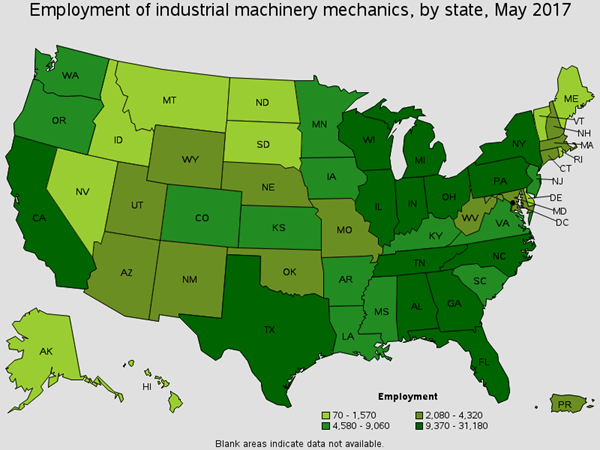

Worker activities include repairing, installing, and adjusting industrial machinery. There are around 2,100 of this occupation works in Exploration, Drilling and Production. You will find these workers cutting and welding metal to repair broken metal parts. Job titles for this position are Fixer, Industrial and Master Mechanic.

Employement of Industrial Machinery Mechanics

Lubricates machines, changes parts, and performs machinery maintenance. Exploration, Drilling and Production employs a little over 5,200 of these workers. You will find these workers cleaning machine and machine parts. Cleaning solvents, oil and metalworking fluids are a definite concern for these workers. Common Job titles for this position are Lubricator, Maintenance Man, and Oiler.

Help move materials across Exploration, Drilling and Production operations. There are around 10,000 of these workers in Oil and Gas extraction. You will find these workers operating conveyors, transporting materials, and operating machines. Common job titles are Laborer and Operator.

This occupation makes many of the PPE related decisions within a mine. They review, evaluate, and analyze work environments. This occupation also design programs and procedures to control, eliminate, and prevent disease or injury caused by chemical, physical, and biological agents or ergonomic factors. There are roughly around 1,000 of these workers found in Exploration, Drilling and Production. You will find these workers recommending safety measures and evaluating workplace safety equipment. Common Job titles for this position are Certified Industrial Hygienist; Chief Safety Officer; Corporate Safety Director; Director Employee Safety and Health; Environmental Health and Safety Manager; Environmental, Health, and Safety EHS Officer; Health and Safety Manager; Risk Control Consultant; Safety Consultant; Safety Specialist

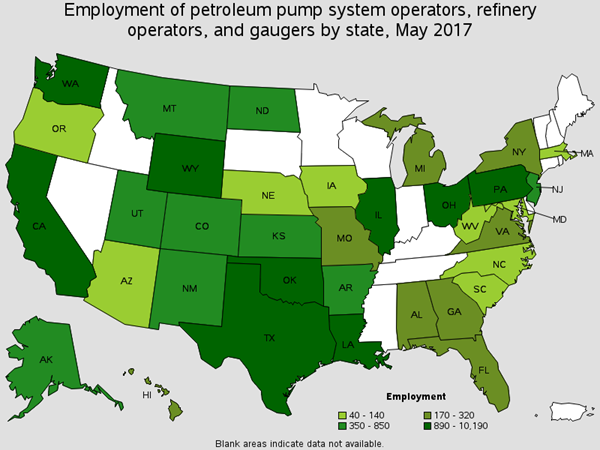

Operate petroleum refining or processing units. There are around 3,800 of these workers in Exploration, Drilling and Production. You will find these workers monitoring gauges, opening valves to regualte the flow of oil, and operating manifold/pumping systems. Common Job titles for this position are Gauger, Head Operator, Pumper, and Refinery Operator

Employement of Petroleum Pump System Operators, Refinery Operators, and Gaugers

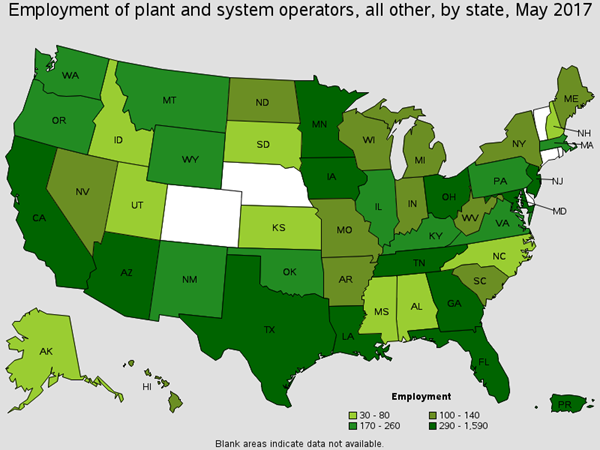

Monitor both input and output to ensure systems are working correctly. There are roughly 5,300 of these workers in Exploration, Drilling and Production. You will find these workers operating valves, engines, generators and pumps to keep everything running smoothly. Common job titles are Process Operator and Operator.

Employement of Plant and System Operators

Operate power-driven, stationary, or portable pumps to transfer gases, oil, other liquids, slurries, or powdered materials to and from various vessels. There are around 900 of these workers in Oil and Gas extraction. You will find these workers tending vessels that store gasses and turning valves. Common job titles for this position are Chemical Operator, Pipeline Operator, and Pumper.

Employement of Pump Operators Station Operators

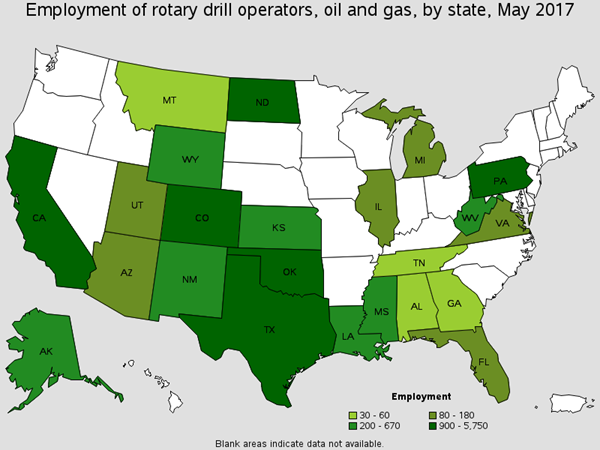

Operate a variety of drills to remove underground oil and gas. They also remove core samples for testing during oil and gas exploration. There are around 1,800 of these workers in Oil and Gas extraction. You will find this worker connecting sections of dril pipe, operating drilling equipment, and raising drill pipes. Common job titles for this occupation are Drill Operator, Driller, and Oil Rig Operator

Employement of Rotary Drill Operators, Oil and Gas

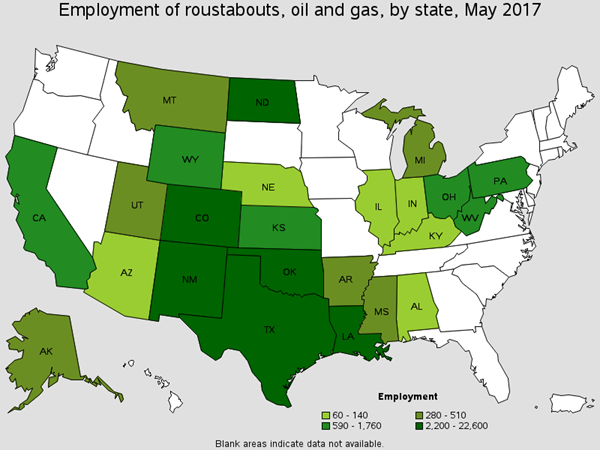

Assemble and repair oil field equipment using hand and power tools. There are around 5,000 of these workers in Exploration, Drilling and Production. You will find these workers tightening pipes, casings and pump rods. The workers move a lot of peipe and bolt together a lot of pumps. Common job titles for this occupation are Floor Hand, Galley Hand and Rig Hand.

Employement of Roustabouts

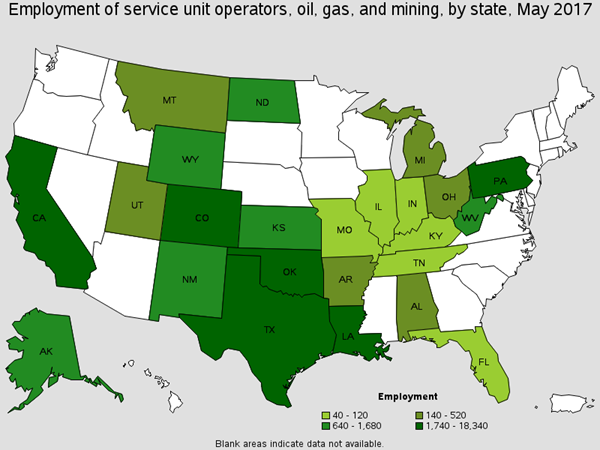

Operate equipment to increase oil flow from producing wells. There are 6,400 of these workers in Exploration, Drilling and Production. They also remove stuck pipe, casing, tools, or other obstructions from drilling wells. You will find these workers installing pressure-control devices, maintaining safety inspections and operating cranes and other lifting equipment. Common job titles are Rig Operator, Tool Pusher, and Wireline Operator.

Employement of Service Unit Operators

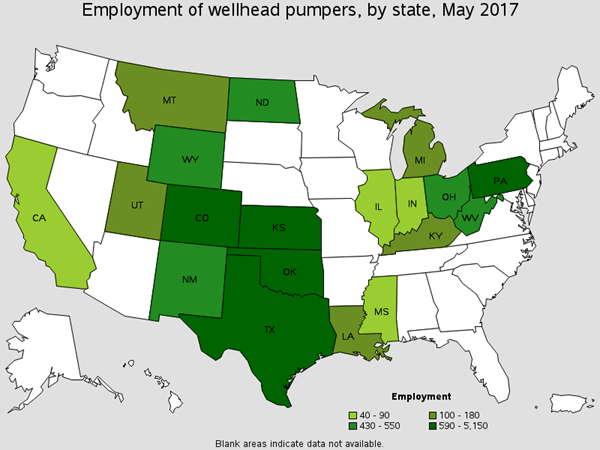

Operate power pumps producing flow of oil or gas from wells. There are around 8,000 of these workers in Exploration, Drilling and Production. You will find these workers operating pumps, unloading pipes and pumping equipment, repairing oil gauges, and performing routine maintenance. Common job titles for this occupation are Oilfield Operator, Pumper, and Well Head Pumper.

Employement of Wellhead Pumpers

Operate machines designed to cut, shape and form metal. There are roughly 400 of these workers in Oil and Gas extraction. You will find these workers fabricating metal products, lifting heavy materials and working with their hands. Common job titles are Sheet Metal worker and Welder. Be sure to check out our Metal Fabrication industry educational page.

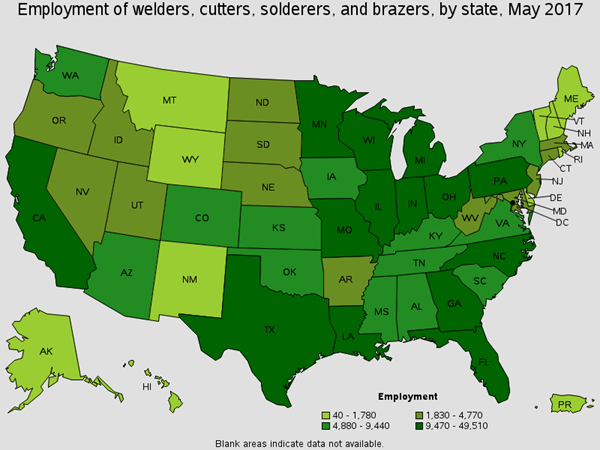

Operate welding, soldering or brazing machines that weld, braze, or heat treat metal products. Exploration, Drilling and Production employs around 300 of these workers. You will find these workers adding material to work pieces, joining metal components, and annealing finished work pieces. Common Job titles for this position are Fabricator, Mig Welder, Spot Welder, Fitter-Welder, and Braze Operators.

Use hand-welding, flame-cutting, hand soldering, and brazing equipment to weld/join metal components, fill holes, indentations, or seams of fabricated metal products. Exploration, Drilling and Production mploys around 300 of these workers. You will find these workers welding components in flat, vertical or overhead positions. Common Job titles for this position are Maintenance Welder, Mig Welder, and Welder/Fabricator

Employement of Welders, Cutters, Solderers, and Brazers

As mentioned above, the Oil and Gas industry recently led the way in advancing major hand protection improvements. For years, Oil and Gas workers wore only general-purpose dotted cotton gloves for most drilling activities. Unfortunately, this type of hand protection provided limited protection to a worker’s back-of-hand. With workers operating around heavy chains, pipes and tongs, there were always a high number of workplace injuries.

In May of 2008, MCR Safety and a worldwide leading Oil & Gas production company began collaborating on the development of a Petrochemical Industry glove. The goal was to create a glove that protected workers’ back-of-hands, helping reduce hand injuries and setting an industry standard for glove protection.

By 2010, there was a confirmed 30% reduction in hand injuries with workers wearing the HV100 glove. In addition, field trials showed an average wear time of 14 working days, much longer than a standard cotton glove could offers. Now, workers are protected with state of the art impact protection, and companies are saving money by replacing fewer gloves! Check out the timeline on our Impact Protection page.

The next chapter of back-of-hand protection is in the works. Industry standards for impact resistance will ensure back-of-hand performance measures are met. Similar ANSI performance standards are well established in other areas like cut-resistance levels. Official industry standards will ensure Oil and Gas worker’s hands are even safer.

Are you ready? Schedule a 360 visit for more information.

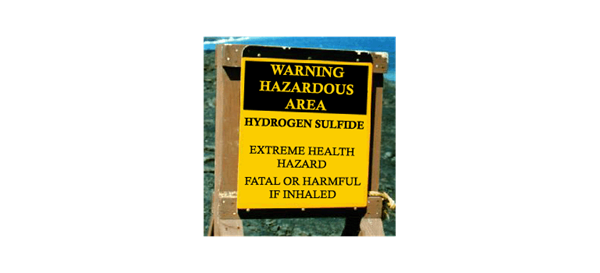

Beyond back-of-hand injuries, exposure to harmful substances is another hazard production workers face every day. Chemical exposure from blow-outs, hydrogen sulphide exposure, heavy metals, benzene in crude, and day-to-day exposure to sludge, grit and sea water. The dangers are endless for those working in Oil and Gas drilling.

"At the end of the day, the goals are simple: Safety and security."

At the end of the day, keeping workers safe is what MCR Safety does. We Protect People! Let us help keep you safe when exploring, drilling and producing oil!

Find the right MCR Safety product that protects you against these common hazards.

Heavy-duty wearing gloves are essential on a drilling rig. Check out our reinforced thumb-crotch ensuring added durability and longevity. Our premium leather gloves are not too shabby either!

Learn More About Abrasive Handling ProtectionCommon Applications:

Hydrogen sulfide occurs naturally in oil and gas. You will need chemical gloves, face shields, and goggles when handling chemicals and opening pressurized systems. Check out our chemical permeation database.

Learn More About Chemicals and Liquids ProtectionCommon Applications:

Blunt force impact is an everyday concern for a rigger. Impact protection is this worker’s best friend. Are you ready for the new impact standard?

Learn More About Crush and Impact ProtectionCommon Applications:

Joining metal components on an oil rig demands the best welding gear.

Learn More About Cutting and Welding ProtectionCommon Applications:

Exposure to fluids is a definite concern for oil production workers. Examples include drilling fluids, water-based mud, hydraulic oil, gear oil, and grease. You will need safety gear made to last!

Common Applications:

Silica is the basic component of sand and rock, meaning dust exposure is common during hydraulic fracturing operations. Conveyor sand, operating engines and motors are all concerns for getting dust in your eye. Lined eyewear will keep it out of your eyes!

Learn More About Dust ProtectionCommon Applications:

Explosions caused by a spark igniting certain vapors or gases is a major concern for workers. Flame resistant gear is mandatory across all production platforms, drilling rigs, and construction barges. Max Comfort gear will keep you safe!

Learn More About Fire and Explosion ProtectionCommon Applications:

Dotted cotton gloves are an industry favorite for light general maintenance. From oil absorption, cushioning and insulation, cotton gloves are still loved by many.

Learn More About General Hazards ProtectionCommon Applications:

Would you like to keep wearing your cotton gloves and have the back of your hand protected? Checkout our MC504!

Learn More About Heat and Crush ProtectionCommon Applications:

There is no shortage of activities on a drilling rig where a worker’s eyes need protected. Splashing chemicals, flying debris, and sparks are concerns every Oil and Gas worker faces.

Learn More About Impaired Vision ProtectionCommon Applications:

Working in the rain and around liquids, plus staying FR compliant has always been a challenge. Not anymore, with Big Jake rainwear protecting workers from ARC flash hazards!

Common Applications:

High-risk activities demand high impact gear! 56% of all recordable incidents in 2014 for Oil & Gas were attributed to "struck by" and "caught between” objects. Back-of-hand protection is a lifesaver, when working with oils, liquids, muds and objects that roll/pinch. Check out our brand new Ninja Alchemy.

Common Applications:

You are going to need steel toed boots for protecting your feet from falling overhead objects, dropped objects and liquid exposure.

Learn More About Liquid and Dropped Objects ProtectionCommon Applications:

Do you need excellent grip working around lubricants, muds and oil. Our new Max Grid pattern takes first prize when it comes to gripping in oil!

Learn More About Oily Grip ProtectionCommon Applications:

High performance gloves are what these workers demand when maintaining pumps and turbines.

Learn More About Pump Maintenance ProtectionCommon Applications:

Working outside involves facing Mother Nature head on, meaning wet conditions are always a concern. HPT coated gloves repels liquids providing a firm wet or dry grip!

Learn More About Repelling Water ProtectionCommon Applications:

Upstream workers are always exposed to sharp metal. Cuts and Lacerations make up 7 percent of all oil and gas injury claims.. Rest assured, we simplify the selection process on our cut protection page. Grip with confidence next time you are handling heavy iron, jagged material and sharp metal!

Learn More About Sharp Objects ProtectionCommon Applications:

Hi-Viz garments distinguish oil & gas workers keeping them seen across drilling operations.

Learn More About Visibility ProtectionCommon Applications:

By incorporating a "Watch Your Hands" logo on the back of the glove, oil and gas workers are reminded of the constant hazards faced.

Learn More About Watch Your Hands ProtectionCommon Applications:

Goggles are excellent for overhead work where particles might fall. They also keep the wind from distracting high-risk work! Impact and chemical protection is a nice feature too.

Learn More About Windy Conditions ProtectionCommon Applications:

Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.