“The danger which is least expected soon comes to us”

Voltaire’s words echo through every mining operation, as dangers and hazards are present at all times. From explosions, to harsh chemicals and dust, miners know that hazards will soon come their way. Mining ranks as one of the top dangerous US industries, specifically underground coal mining. Because of the countless hazards faced, workers lean on MCR Safety for premier safety gear protecting them at work and home.

Whether you know it or not, mining is essential to man’s modern progress and responsible for all the wonderful amenities we sometimes take for granted. Mining provides the coal needed to power our electrical plants. The very computer you are using now most likely get its power from electrical power plants needing coal. Next time you pick up that iPhone, thank the miner that helped extract the gold found in it.

Iron Ore, a mineral, provides the necessary ingredient for creating steel, the building block of our modern buildings, cars, trains and ships. Last but not least, Quarrying provides the material needed to build houses, roads and great monuments. Ever since the Industrial Revolution began in the 1800’s, we have depended on mining like no other time in history.

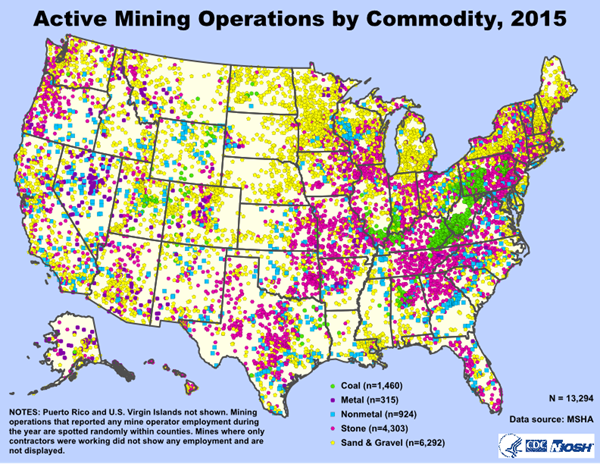

MSHA's map highlighting mining operations across the US

Mining is broken down into sub-industries based around the metals and minerals developed and produced. The mining industries employing the most workers: Click on a sub-industry to expand and learn more.

This industry employs over 94,000 workers responsible for mining gravel, clay, rock, sand and stone

This industry employs over 49,000 workers extracting coal from the ground.

This industry employs around 15,000 workers engaged in mining metal ore.

This industry employs around 15,000 workers engaged in mining metal ore.

This industry employs around 5,500 workers engaged in mining iron ore.

Click a source to expand and learn more.

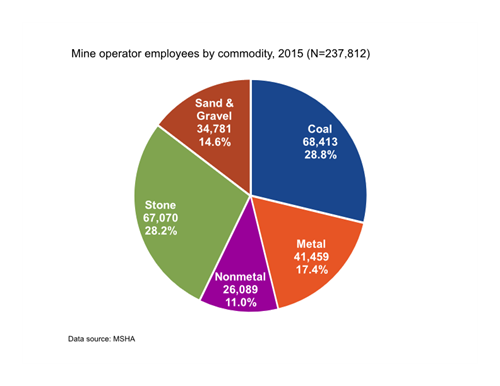

Mine operator employees by commodity

[Texas, California, Pennsylvania, Ohio, Illinois, Kentucky, Tennessee, Oregon, Minnesota, Vermont]

[Wyoming, West Virginia, Kentucky, Pennsylvania, Illinois, Indiana, Ohio Utah]

[Arizona, Utah, New Mexico, Nevada and Montana]

[Alaska, Nevada, Idaho, Utah]

[Michigan and Utah.Most US Iron is found in Minnesota’s Mesabi Range.]

Click a mine type to expand and learn more.

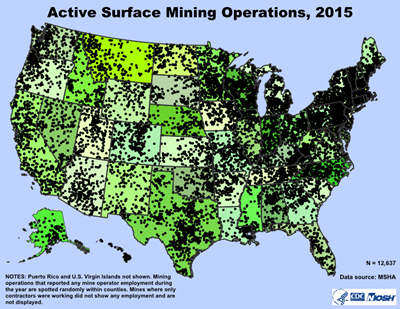

Minerals are directly removed from the ground surface area.This process is commonly known as “open cast mining”and makes up the majority of mining operations. More than 95% of all non-metallic minerals involve this type of mining.

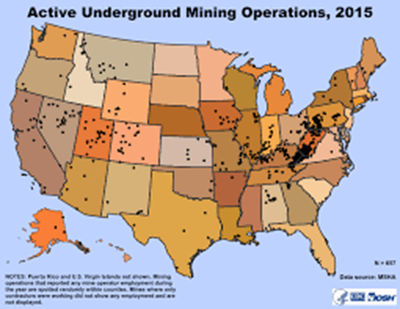

With this type of mining, surface area remains in one piece and minerals are removed through tunnels and shafts. Some of the most dangerous working conditions can be found in underground mines. Underground mines are often found in Coal mining.

Dredging is more of a process, rather than a physical mine. Minerals are removed from the floor of a body of water.

Companies engaged in mining operations follow a typical process for extracting metals and minerals out of the ground. Here is the typical process:

| 1st Phase | 2nd Phase | 3rd Phase |

|---|---|---|

ExplorationStudies and mapping |

DevelopmentConstruction of mine |

ProductionExtracting the mineral from the ground |

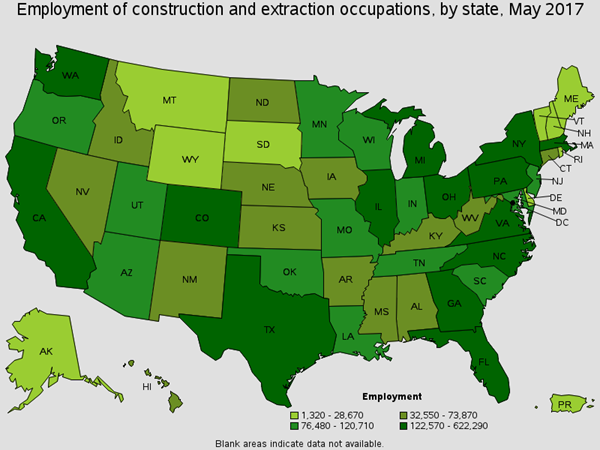

The development stage is where you will find many workers, with over 30% of the mining workforce involving construction and extraction workers. The coal industry employs the highest number, with over 40% construction workers. Mines require a lot infrastructure: such as roads, buildings, shafts, boards and pillars, head frames, electrical, pipes, and ventilation systems. Be sure to check out our Construction Page for a deeper look into Construction hazards.

Beyond construction workers, each mining industry is unique when it comes to the occupations found. You will find more roof bolters in the coal mining industry, more metal workers in metal ore mining and more rock splitters in quarrying. Do not worry, we separately breakdown each industry and the hazards faced by workers.

In total, the Bureau of Labor Statistics reports there are over 180,000 workers found across the Mining Industry.

Here are some of the main occupations found, where safety gear is required.We highlight the number of workers from each occupation, what they do, and their common job titles.

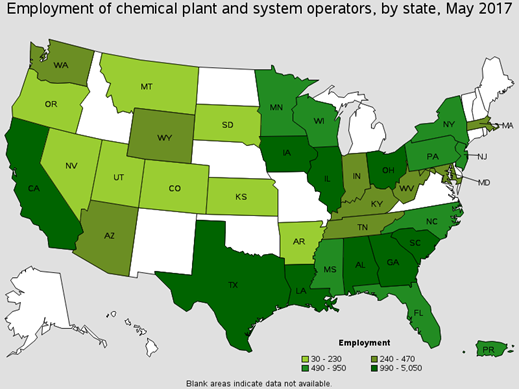

Operate equipment to control chemical changes or reactions in the processing of industrial products. There are roughly around 1,600 of these workers found in Mining. You will find these workers detecting equipment leaks and drawing samples of products. Common Job titles for this position are Multiskill Operator, Production Operator, and Spray Dry Operator.

Employment of Checmial Plant and System Operators by State

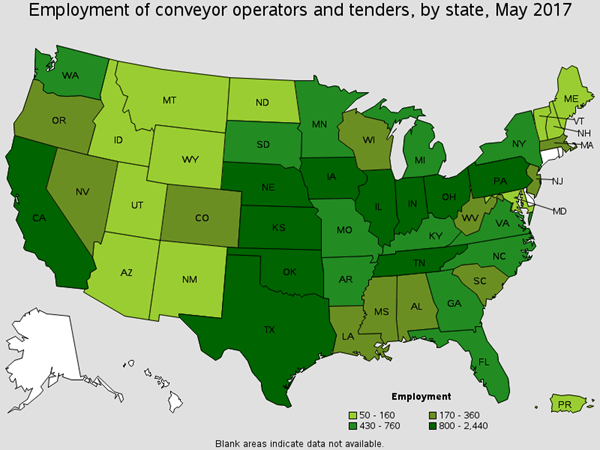

Tend conveyors or conveyor systems that move materials or products to and from stockpiles, processing stations, departments, or vehicles. There are roughly around 1,200 of these workers found in Mining. You will find these workers loading materials, clearing jams, and removing damaged materials. Common Job titles for this position are Chipper Operator, Flumer, Process Operator and Strapper Operator.

Employment of Conveyor Operators and Tenders by State

Employment of Construction and Extraction Occupations by State

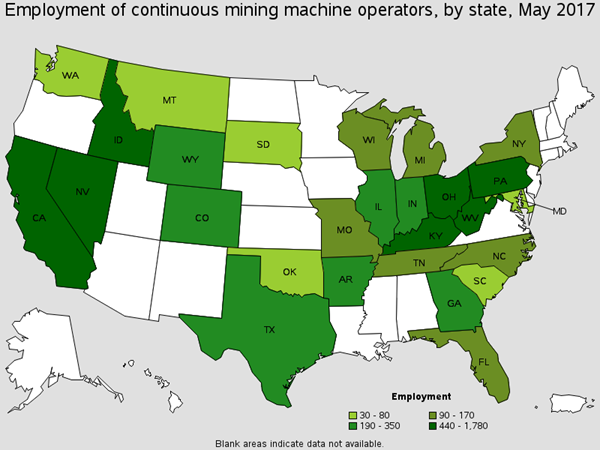

Operate mining machines that rip coal, metal and nonmetal ores, rock, stone, or sand from the mine face and load it onto conveyors or into shuttle cars. There are roughly around 11,000 of these workers found in Mining. You will find these workers assisting in construction activities, checking the roof stability and cleaning equipment. Common Job titles for this position are Bore Mine Operator, Miner Operator, and Continuous Miner.

Employment of Continuous Mining Machine Operators by State

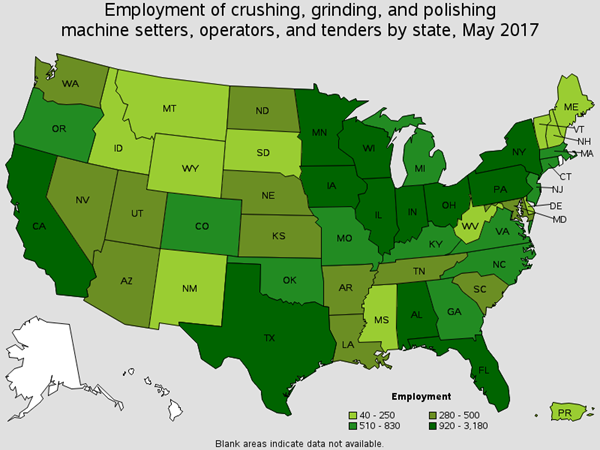

Operate machines to crush, grind, and polish materials. There are roughly around 4,490 of these workers found in mining. You will find these workers mixing chemicals, collecting materials and using picks. Common Job titles for this position are Batch Mixer, Fabricator, and Miller.

Employment of Crushing, Grinding, and Polishing Machine Setters, Operators, and Tenders by State

Operate dredge to remove sand, gravel, or other materials in order to excavate and maintain navigable channels in waterways. There are roughly 12,000 of the workers found in Mining. You will find these working operating equipment, tools and gauges. Common Job titles for this position are Dredge Operator and Dredger.

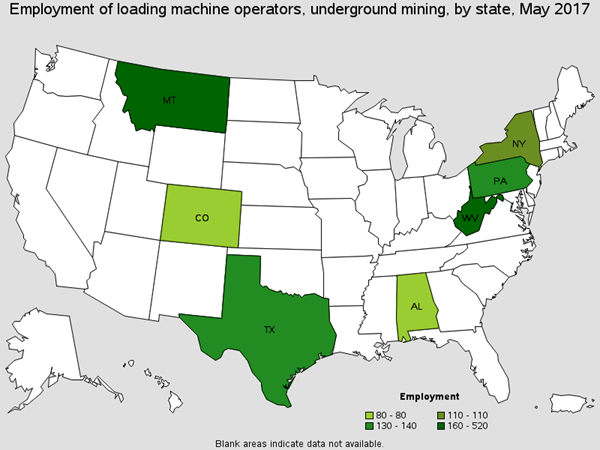

Employment of Loading Machine Operators by State

Operate a variety of drills to facilitate the use of explosives in mining or construction. There are roughly around 1,200 of these workers. You will find these workers mixing chemicals, collecting materials and using picks. Common Job titles for this position are Blast Hole Driller, Rock Drill Operator, and Underground Drill Operator.

Install, maintain, and repair electrical wiring, equipment, and fixtures. Around 4,100 of this occupation in Mining. You will find these workers connecting wires to breakers and transformers, making dielectric and FR Safety Gear important. Common Job titles for this position are Industrial Electrician, Journeyman Electrician and Wireman, and Maintenance Electrician.

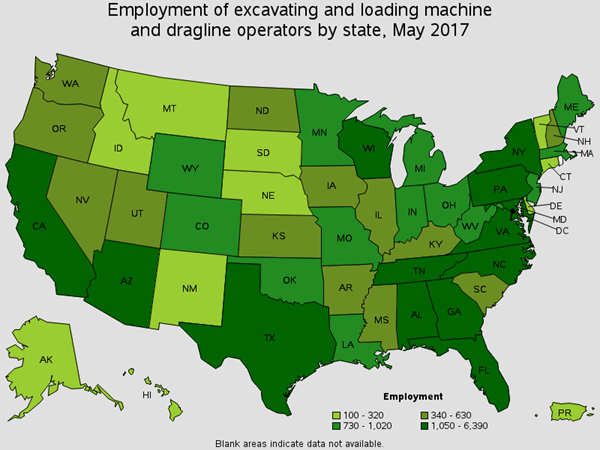

Operate machinery equipped with scoops, shovels, or buckets, to excavate and load loose materials. There are around 10,000 of these workers in the Mining Industry. You will find these workers breaking rock and operating power shovels. Common job titles for this occupation are Pit Operator, Loader Operator, and Dragline Oiler.

Employment of Excavating and Loading Machine and Dragline Operators by State

Help craft workers by supplying equipment, cleaning areas, and repair drilling equipment. Extraction craft workers are earth drillers, blasters and explosives workers, derrick operators, and mining machine operators. There are around 31,000 of these workers. Common Job titles for this position are Blasting Helper, Miner Helper, and Driller Helper.

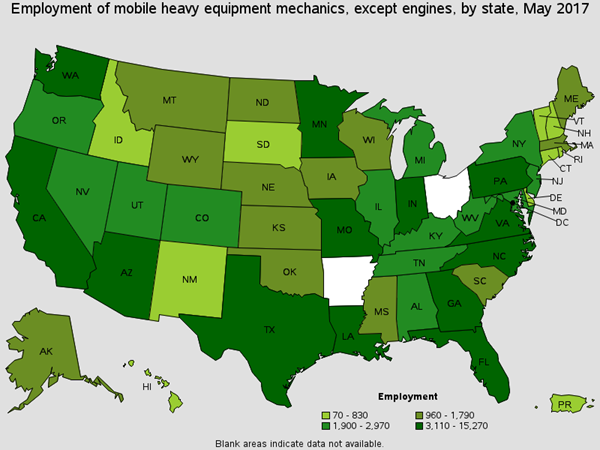

Repair overhaul mobile mechanical, hydraulic, and pneumatic equipment. Examples of this equipment includes cranes, bulldozers, graders, and conveyors. There are around 8,300 of these workers found. You will find these working replacing worn parts and reassembling heaving equipment with tools. Common Job titles for this position are Heavy Equipment Technician, Field Mechanic, and Mobile Heavy Equipment Mechanic.

Lubricates machines, changes parts, and performs machinery maintenance. Mining employs a little over 7,900 of these workers. You will find these workers cleaning machine and machine parts. Cleaning solvents, oil and metalworking fluids are a definite concern for these workers. Common Job titles for this position are Lubricator, Maintenance Man, and Oiler.

Worker activities include repairing, installing, and adjusting industrial machinery. There are around 5,500 of this occupation works in Mining. You will find these workers cutting and welding metal to repair broken metal parts. Job titles for this position are Fixer, Industrial and Master Mechanic.

Inspect machined, fabricated or assembled parts. There are around 2,200 of these workers in Mining. You will find these workers inspecting materials and structures. Common Job titles for this position are Quality Technician, Inspector, and Picker / Pacer.

Manually move materials to perform general labor. Around 3,900 of these workers are in the mining industry. You will find this occupation loading docks and loading materials to production areas. Common job titles for this position are laborer and material handler.

Operate underground loading machine to load coal, ore, or rock into shuttle / mine car or onto conveyors. There are around 1,900 of these workers found in Mining. You will find these prying off loose material from roofs, cleaning hoppers, and cleaning spillage. Common Job titles for this position are Miner, Production Miner, Shuttle Car Operator, and Under Ground Miner.

Operate machines designed to cut, shape and form metal. There are roughly 2,500 employees found for this occupation. You will find this worker fabricating metal products, lifting heavy material and working with their hands. Common job titles for this position are sheet metal worker and welder. Be sure to check out our Metal Fabrication industry educational page.

Keep machines, mechanical equipment, or the structure of an establishment in repair. There are around 26,000 of these workers are in the Mining Industry. You will find these workers pipe fitting, repairing equipment, and repairing buildings. Job titles for this position are Maintenance Worker, Maintenance Mechanic, and Facilities Manager.

Help move steel and other materials. Around 22,000 of these workers help move steel and other material across in Mining. That is a large number of hands needing protected. You will find these workers operating conveyors, transporting material, and operating machines. Common job titles are laborer and operator.

Operate machinery such as longwall shears, plows, and cutting machines to cut or channel along the face or seams of coal mines, stone quarries, or other mining surfaces to facilitate blasting, separating, or removing minerals or materials from mines. There are around 3,500 of these workers found in Mining. You will find these workers positioning roof supports, preventing cave-ins and cutting entries between rooms. Common job titles for this position are Bore Miner Operator, Underground Miner and Shear Operator.

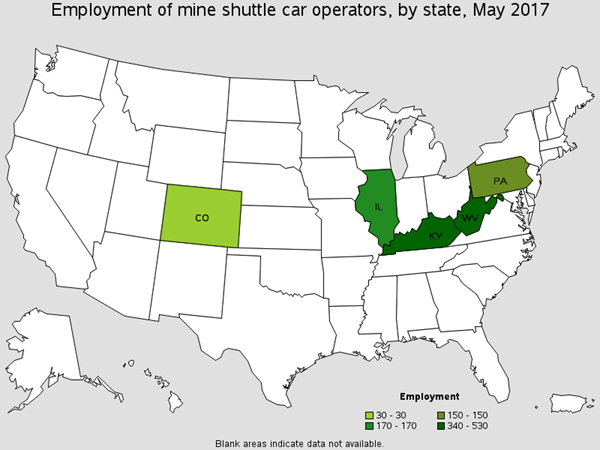

Operate diesel or electric-powered shuttle cars in underground mines to transport materials from working face to mine cars or conveyors. There are roughly around 1,400 of these workers found in Mining. You will find these workers attaching drill bits and drill rods. Common Job titles for this position are Coal Haul Operator and Shuttle Car Operator.

Employment of Mine Shuttle Car Operators by State

Repair, or overhaul mobile equipment, such as cranes, bulldozers, graders, and conveyors, used in construction, logging, and surface mining. There are roughly around 8,000 of these workers found in Mining. You will find these workers replacing worn parts and reassembling equipment using hand tools. Common Job titles for this position are Heavy Equipment Technician, Field Mechanic, and Equipment Mechanic.

Employment of Mobile Heavy Equipment Mechanics, Except Engines, By State

This occupation makes many of the PPE related decisions within a mine. They review, evaluate, and analyze work environments. This occupation also design programs and procedures to control, eliminate, and prevent disease or injury caused by chemical, physical, and biological agents or ergonomic factors. There are roughly around 600 of these workers found. You will find these workers recommending safety measures and evaluating workplace safety equipment. Common Job titles for this position are Certified Industrial Hygienist, Chief Safety Officer, Corporate Safety Director, Director of Employee Safety and Health, Environmental Health and Safety Manager, Environmental Health and Safety, EHS Officer, Health and Safety Manager, Risk Control Consultant, Safety Consultant and Safety Specialist.

Operate machines preparing products for storage or shipment. There are around 1,000 of this occupation that works in Mines. You will find these workers inspecting products and removing packaged items. Job titles for this position are Machine Operator, Packaging Operator, and Fabrication Technician.

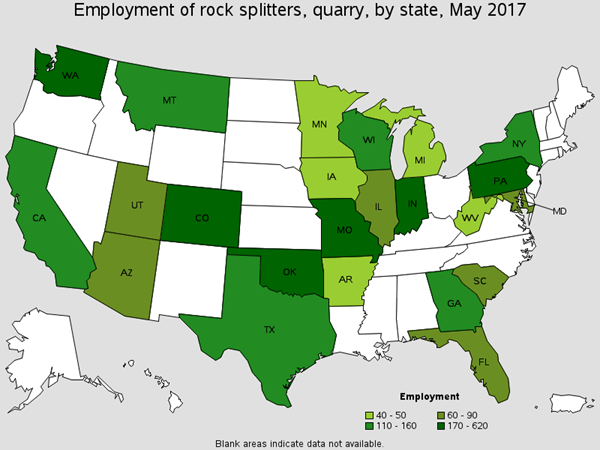

Operate blocks of rough dimension stone from quarry mass using jackhammer and wedges. There are around 3,300 of this occupation working in mines. You will find these workers removing pieces of stones, cutting slabs, and inserting wedges into holes. Outdoor weather is always a concern for this occupation. Job titles for this position are Rock Splitter, Blaster, and Driller.

Employment of Rock Splitters by State

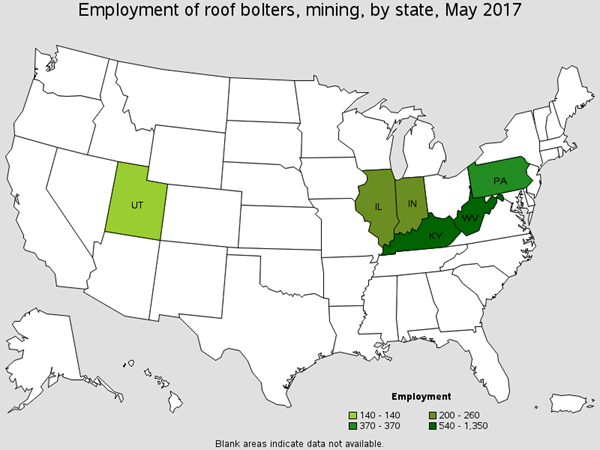

Operate machinery to install roof support bolts in underground mine. There are around 3,200 of this occupation working in mines. You will find these workers pulling down loose rock, drilling holes and positioning machines. Outdoor weather is always a concern for this occupation. Job titles for this position are Bolt Man, Bolter, and Underground Miner.

Employment of Rock Bolters by State

Operate continuous flow / vat-type equipment, filter presses, shaker screens, centrifuges, scrubbing towers, and batch stills. There are roughly around 1,600 of these workers found in Mining. You will find these workers pouring unrefined material into machines. Common Job titles for this position are Machine Tender and Plant Operator.

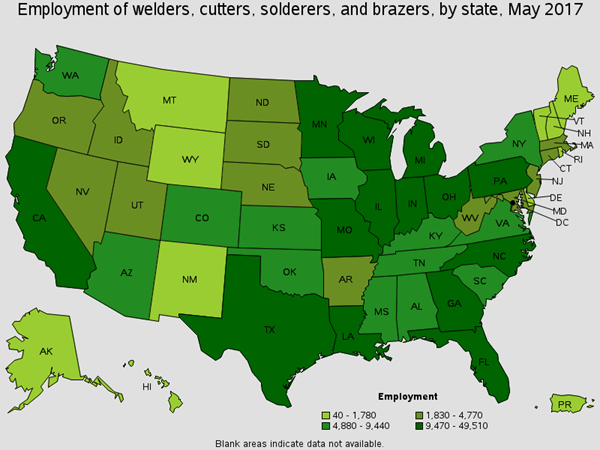

Operate welding, soldering or brazing machines that weld, braze, or heat treat metal products. The mining industry employs around 1,700 of these workers. You will find these workers adding material to work pieces, joining metal components, and annealing finished work pieces. Common Job titles for this position are Fabricator, Mig Welder, Spot Welder, Fitter-Welder, and Braze Operators.

Employment of Welders, Cutters, Solderers, and Brazers by State

Use hand-welding, flame-cutting, hand soldering, and brazing equipment to weld/join metal components, fill holes, indentations, or seams of fabricated metal products. There are around 1,700 of these workers are employed in Mining. You will find these workers welding components in flat, vertical or overhead positions. Common Job titles for this position are Maintenance Welder, Mig Welder, and Welder/Fabricator.

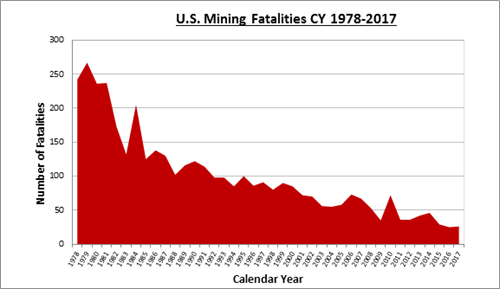

Since mining produces some of the most dangerous working environments, a company's safety awareness, safety culture and safety procedures are paramount. Over the past 100+ years there have been 11 different Safety acts passed through legislation ensuring mining workers are safe. The most recent and well-recognized safety measure is the creation of Mining Safety Health and Administration (MSHA) in 1977, which enforces safety and health rules across U.S. mines. MSHA enforcement of safety rules has paid off, as you can see with the reduced number of fatalities.

The good news is that the average recordable injury cases found across the entire mining industry is only 2.5 for every 100 workers. With that said though, the Coal Mining Industry has 32% more injuries than the average, so not all mining conditions can be treated the same.

In the movie Lord of the Rings, Gimli, the dwarf miner says, “If anyone was to ask for my opinion, which I note they're not, I'd say we were taking the long way round. He tells Gandalf the Wizard; we could pass through the Mines of Moria”. Gandalf says “No Gimli, I would not take the road through Moria unless I had no other choice." Well, we at MCR Safety know entering a mine is dangerous and not always an easy choice due to the many hazards faced. There might not be bad guys lurking in the shadows like in Lord of the Rings but there are plenty of risks a miner takes every time they enter a mine.

Whether you are working in a surface mine, an underground mine or moving material across mines, MCR Safety has the protective safety gear you need. It is what we do, We Protect People! Get ready to gear up and head into those mines!

Learn more about MCR Safety product features that protect against these common hazards.

Click "Learn More" to find info on protecting yourself against these hazards and find the right gear for the job.

Why MCR Safety Products?

Why MCR Safety Products?

MCR Safety manufactures and supplies Personal Protective Equipment (PPE). Simply put, WE PROTECT PEOPLE! We are known world-wide for our extensive product line depth surrounding gloves, glasses, and garments spanning across numerous industries. We offer the total package of safety gear encompassing industrial gloves, safety glasses, protective garments, welding gear, industrial boots, Flame Resistant (FR) gear, face shields, and much more. From a glove standpoint alone, MCR Safety manufacturers and supplies over 1,000 different style gloves. Here are some of the many reasons MCR Safety is your go to source for PPE:

MCR Safety is recognized as a global manufacturer stretching across six countries, with both distribution and manufacturing facilities. Our core competency and specialty is manufacturing and supplying protective gloves, glasses, and garments. The information shown and provided on MCR Safety’s website, its safety articles, industry resource pages, highlighted hazards and safety equipment should be used only as a general reference tool and guide. The end user is solely responsible for determining the suitability of any product selection for a particular application. MCR Safety makes no guarantee or warranty (expressed or implied) of our products’ performance or protection for particular applications.